A team of researchers design sub-nanoporous, selective membranes for water treatment using self-assembled liquid crystal (LC) monomers. The membranes show salt rejection ability, ion selectivity, and excellent water permeability.

![Nanostructured Water Treatment Membranes Based on Thermotropic Liquid Crystals [Video]](https://www.advancedsciencenews.com/wp-content/uploads/2018/02/advs20170405_ASN_image.png)

![Nanostructured Water Treatment Membranes Based on Thermotropic Liquid Crystals [Video]](https://www.advancedsciencenews.com/wp-content/uploads/2018/02/advs20170405_ASN_image.png)

A team of researchers design sub-nanoporous, selective membranes for water treatment using self-assembled liquid crystal (LC) monomers. The membranes show salt rejection ability, ion selectivity, and excellent water permeability.

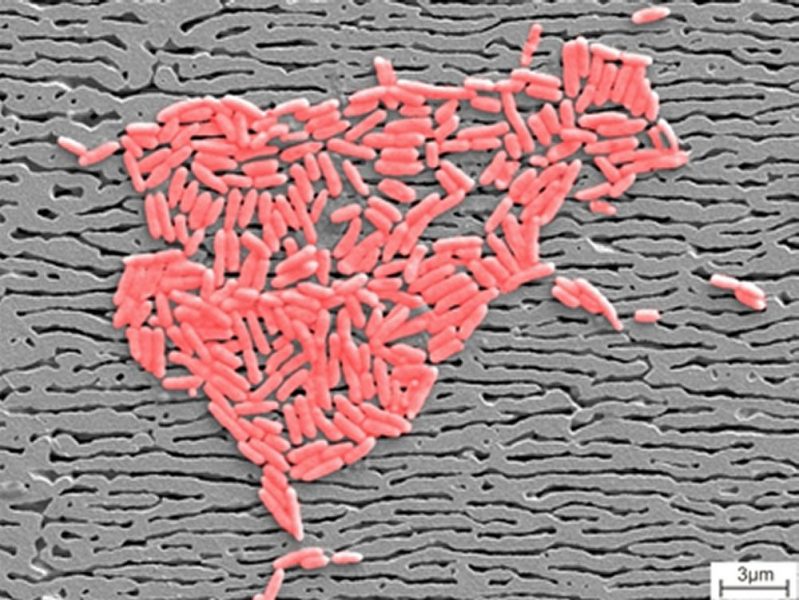

Low temperature plasmas (LTPs) show promise as efficient green technologies for enhancing productivity while maintaining good food quality and safety in the many steps of the food cycle. As a result, applications of LTPs in agriculture have led to creation of a new, rapidly developing field called “plasma agriculture.”

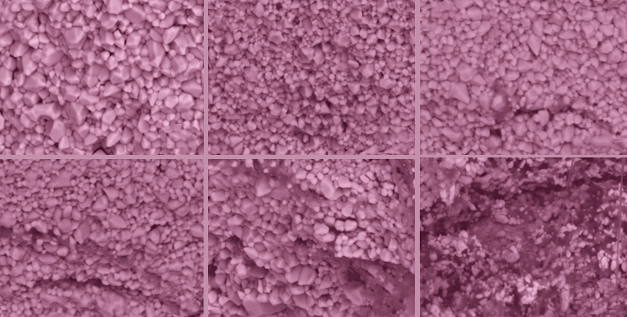

It is shown that polymer such as Teflon can be distributed around each grain of ZnO, and this, in turn, allows for use to form a composite material with an electrical conduction that is blocked at low fields and conducts at high field through the quantum mechanical process known as “tunneling”.

Ni-based superalloys, hitherto utilized exclusively for high temperature applications, e.g. as turbine blades in aero engines, are used to prepare heat-resistant membranes.

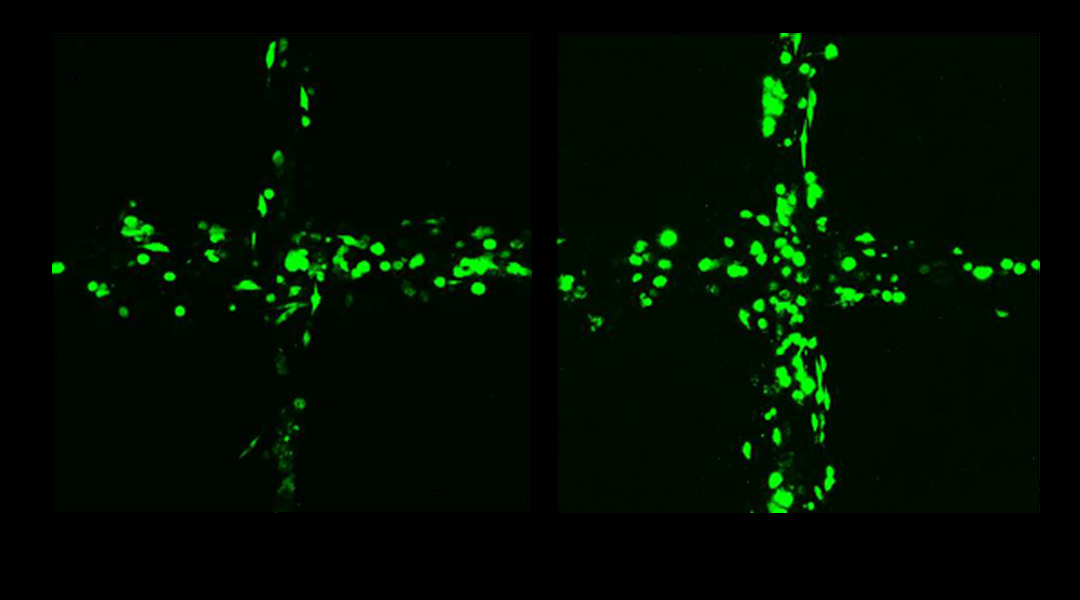

Cell printing using this new electro-hydrodynamic technique allows the creation of cell structures with multiple layers and a high cell viability.

A team of researchers found an innovative way of curing ham by using plasma-treated water as an alternative to chemical curing solutions.

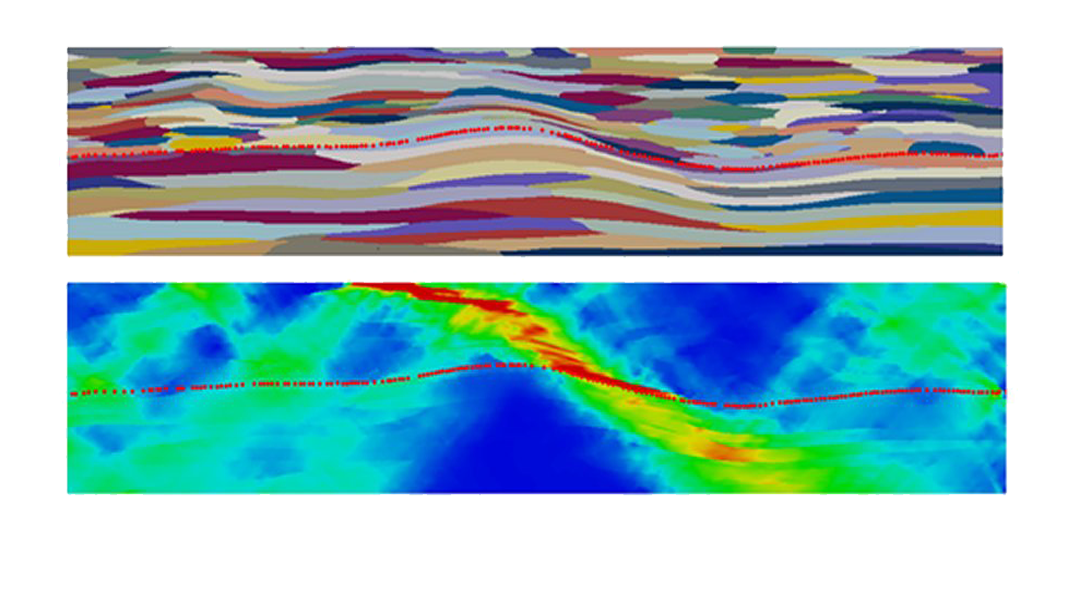

This review emphasizes the importance of the physics-based plasticity theory in constitutive material descriptions for more accurate simulations of deformation in the development of metal forming processes, for controlling mechanical behavior via tailoring microstructural features, and for subsequent component performance testing.

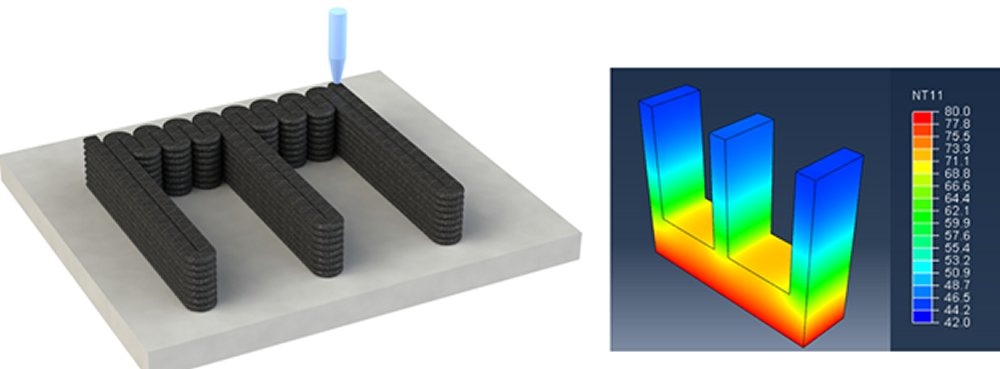

Recent research results in fabricating thermal management devices using 3D printing methods are reviewed.

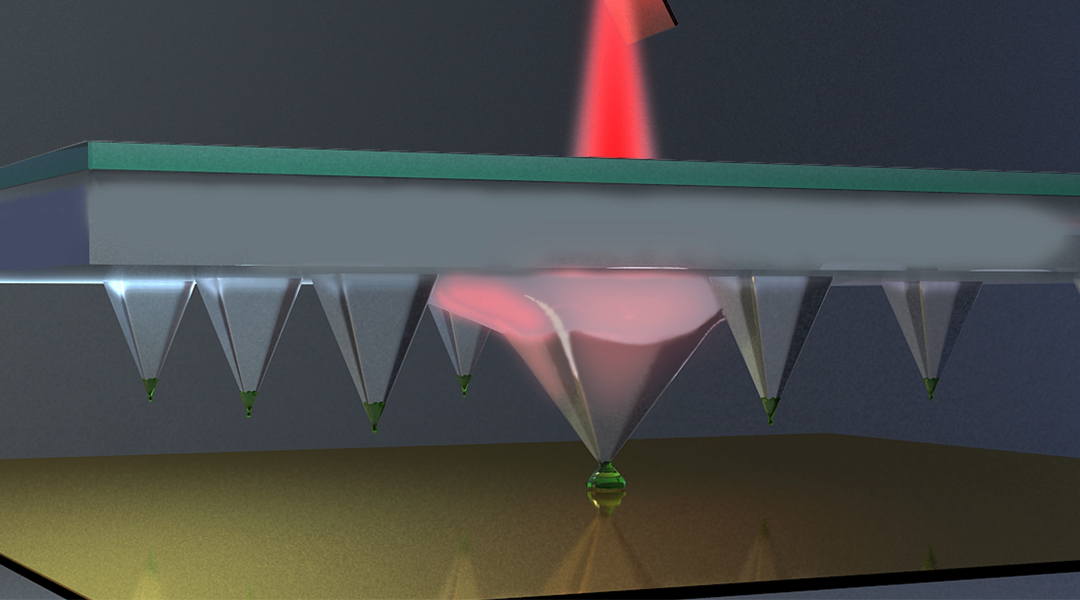

Local control of pens in a large-scale pen array can be achieved by using a nanotube composite that is photo-responsive to fabricate each individual pen.

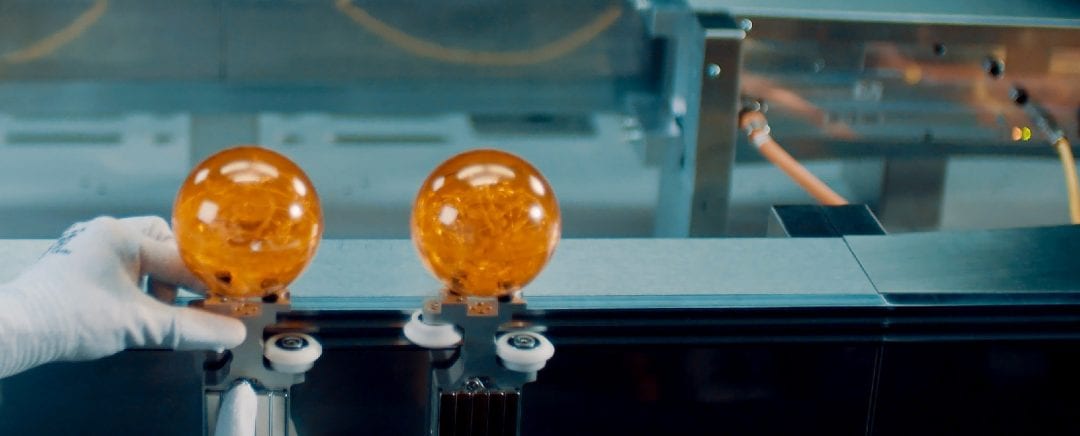

New transport system is pledging to boosts overall equipment effectiveness