Nanoporous materials play an important role in daily life. For example, they are used as tap water filters in intense care units of hospitals to protect immuno-compromised patients from bacterial infections.

While polymer- and ceramic-based nanoporous materials are readily available, it is tough to produce them from metals. This is unfortunate, because metals have specific advantages such as high strength, thermal/electrical conductivity and, in contrast to polymer membranes, heat resistance. The latter aspect is, for instance, important to allow for sterilization of filters in medical applications.

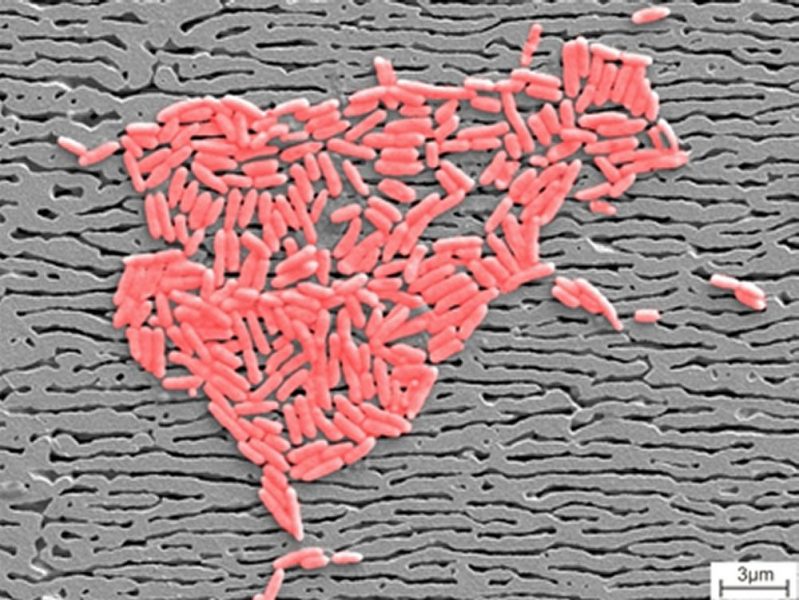

Pseudomonas bacteria on a single crystalline γ′-membrane produced by creep deformation.

Researchers at the Technical University Braunschweig present a new approach to produce nanoporous metallic materials as presented in a review article published in Advanced Engineering Materials.

They use so-called Ni-based superalloys, hitherto utilized exclusively for high temperature applications, e.g., as turbine blades in aero-engines. Like in a woven sweater containing yarns of two different colors, they use two different phases and “weave” them such that each phase is in itself continuous like one yarn but both are intertwined. Then they remove one “yarn”, leading to pores at its prior location while the remaining “yarn” builds the rigid structure of the membrane material.

Unlike to a yarn in a sweater, the thickness of the “yarn” used here is of the order of some hundred nanometers and so are the typical dimensions of the pores. While specific thermo-mechanical treatments are used to form the intertwined network of both phases, an (electro-)chemical process is utilized to selectively remove one of them.

At present, these so-called nanoporous superalloy membranes can only be reliably produced in relatively small quantities form single crystalline superalloys. To overcome this limitation, the researchers at Technical University Braunschweig are currently exploring a new manufacturing route using polycrystalline superalloys in conjunction with a rolling process. If successful, it will allow to produce these novel materials in essentially unlimited quantities.