Researchers develop sustainable source materials for 3D printing. such as single-polymer composites that reinforce themselves and materials derived from waste based plastics.

Researchers develop sustainable source materials for 3D printing. such as single-polymer composites that reinforce themselves and materials derived from waste based plastics.

RapidFit introduces a modular system based on 3D Printing for faster time-to-market and lasting cost reductions in automobile development.

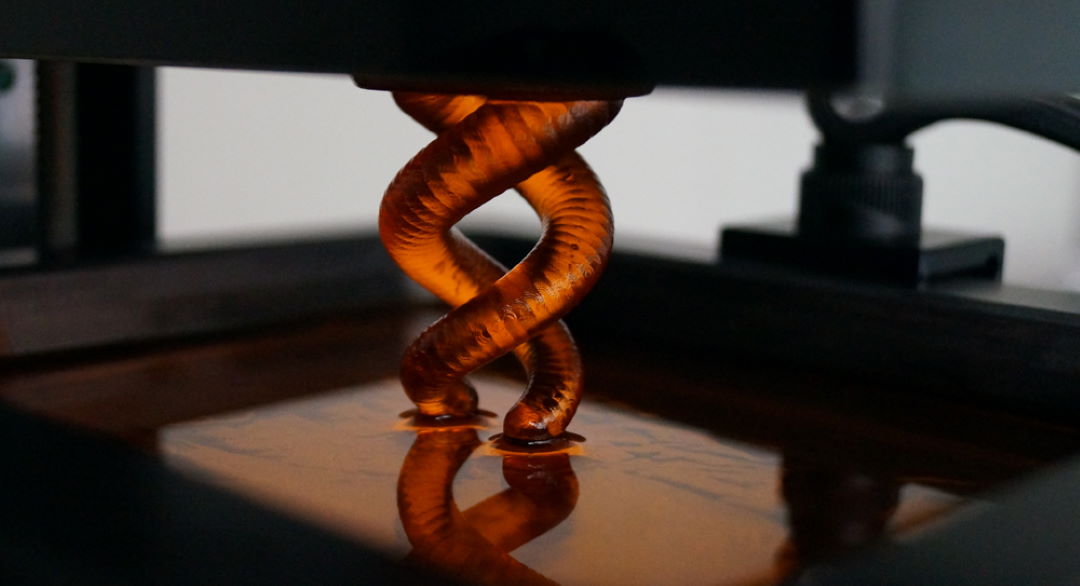

A cooperation between research and industry successfully improves resin-based 3D printing.

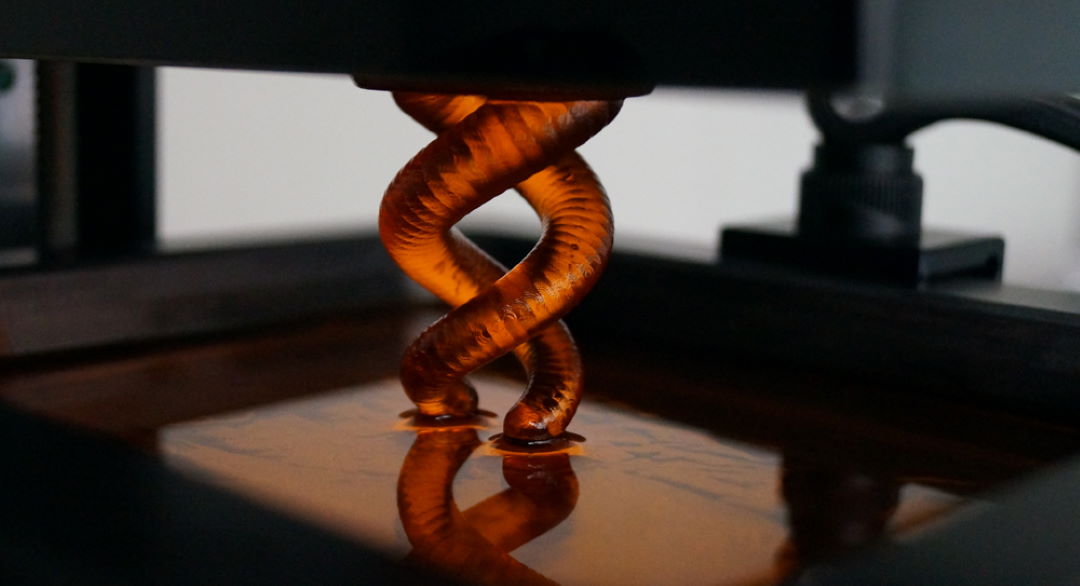

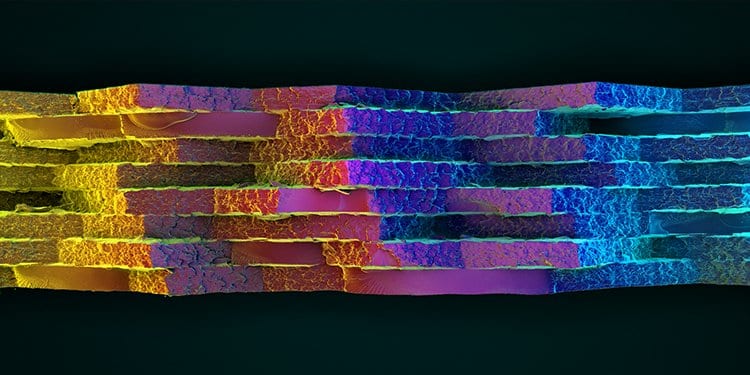

The use of Polyjet 3D printing technology to fabricate novel complex and architected lightweight cellular co-continuous composites has been proposed.

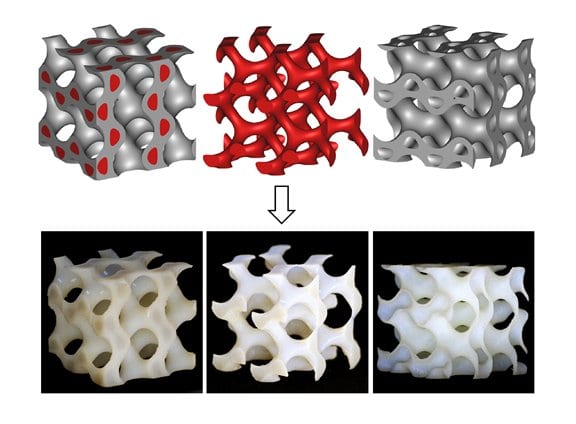

Professor Yingfang Ao from Peking University Third Hospital, Haifeng Chen from Peking University, and colleagues use 3D printing to generate a silk fibroin/gelatin scaffold for knee cartilage regeneration.

Parametric modeling tools from the architectural design world are combined with 3D printing and material testing technologies from materials science to populate gaps in anatomical space.

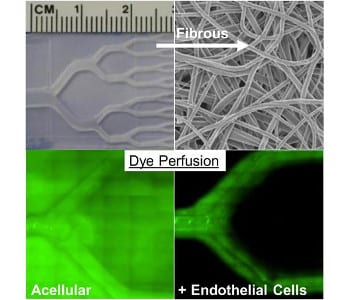

A combination of 3D printing and electrospinning can be used for micropatterning fibrous scaffolds that are suturable, porous, and biodegradable.

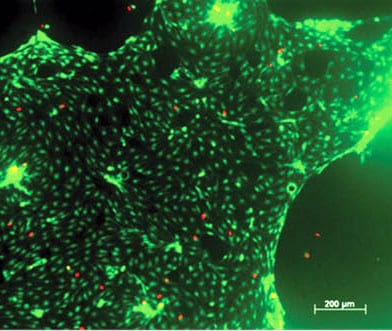

A biocompatible polyacrylate network for the build-up of artificial tissues is created by a 3D printing process.

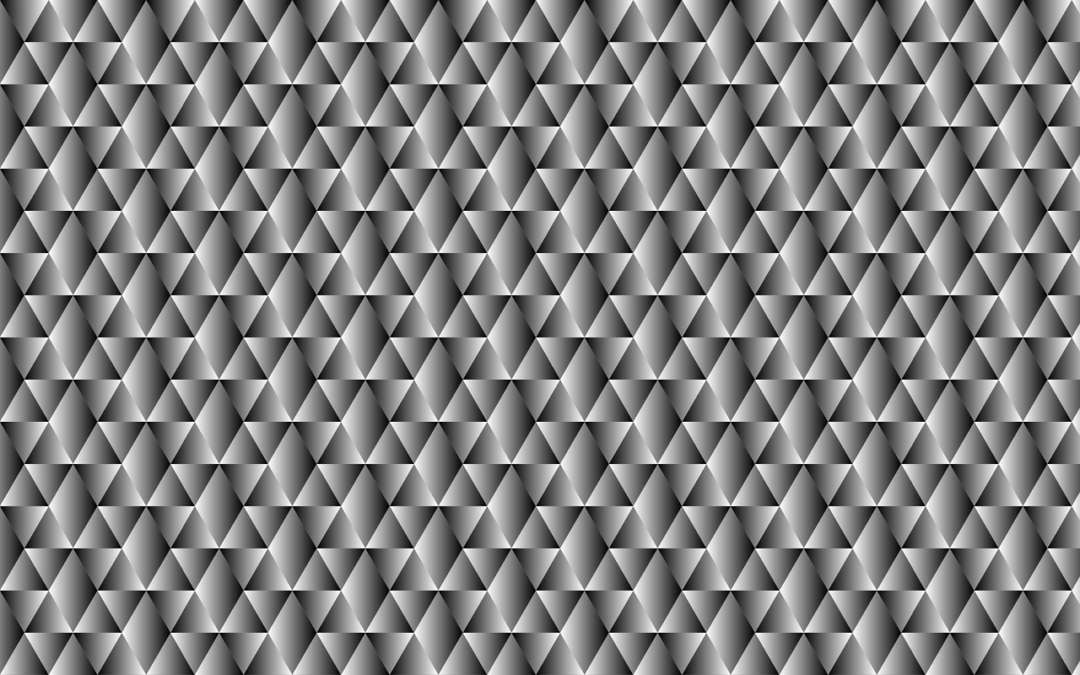

Engineers have developed tactile sensors with increased sensitivity, thanks to auxetic mechanical metamaterials.

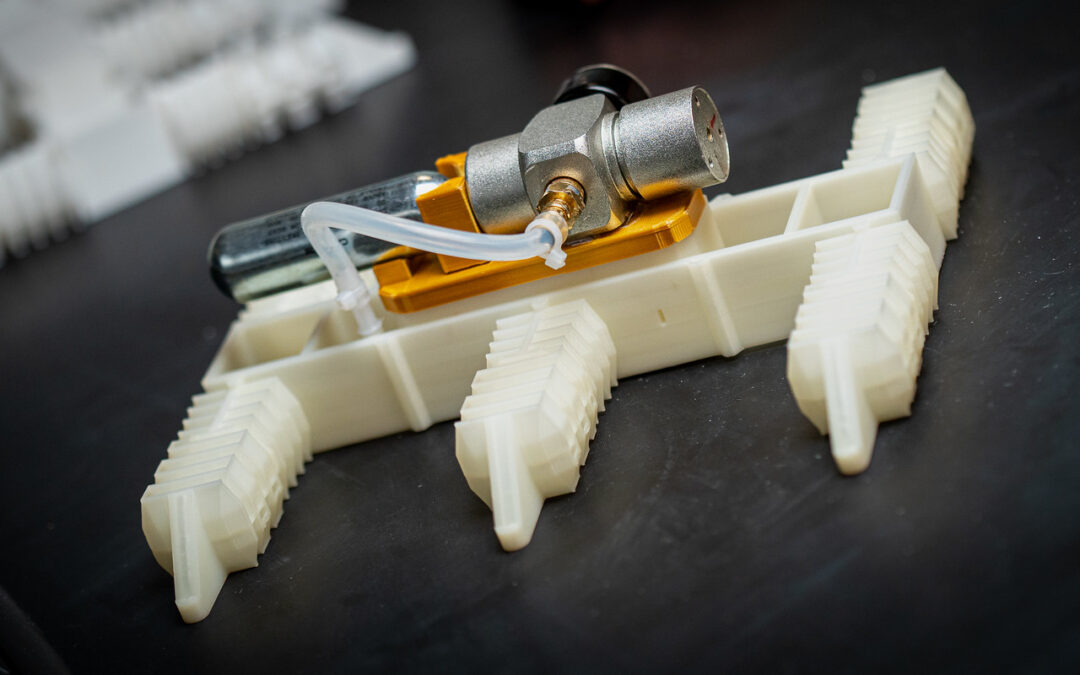

Robot fabrication in a single step with a desktop 3D printer and pressurised gas.