Nature produces a remarkable diversity of structural materials with mechanical properties enviable to materials engineers. One example, the mother of pearl (nacre) layer of mollusk shells, is a laminated brick-and-mortar-like structure of calcium carbonate plates separated by thin sheets of biopolymers, granting a peculiar mixture of high stiffness and fracture toughness. Although these material properties have intrigued researchers for over 100 years, the structural factors influencing the performance of nacre, and other biological materials, have remained elusive due to inherent challenges in linking individual ultrastructural features with their effects on a material’s overall mechanics. Our ability to define the advantages and limitations of designs from nature’s workshop largely hinges on the availability of natural alternatives and controls for comparison, which are often scarce in biology.

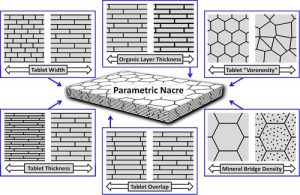

Conceptual schematic of the parametric work flow for the generation of 3D printable nacre mimics. More information and videos in the manuscript and supporting information.

In a new study, Frølich et al. have developed a methodology to address these issues, combining parametric modeling tools from the architectural design world with 3D printing and material testing technologies from materials science to populate gaps in anatomical space. The result is an effective way to rapidly generate biologically inspired “design families” and screen advanced materials design space, to hone in on the mechanical contributions of individual structural features and map out salient engineering principles.

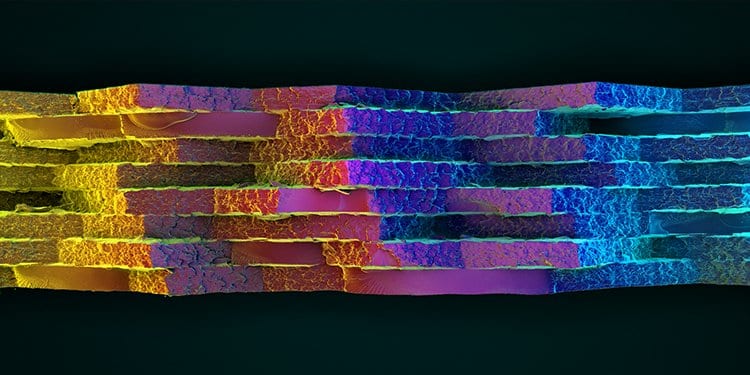

The authors use mollusk nacre as a case study to demonstrate the approach, starting with a computer reconstruction of the material, then using parametric modeling to systematically generate a host of both bio-similar and hypothetical nacres through iterative variation of fundamental features of the tissue. The resultant models were fabricated using multi-material 3D printing, combining polymeric materials emulating the stiff inorganic and pliant organic components of nacre, and tested mechanically.

The resultant high-throughput work-flow is much more efficient than was possible with previously available methods. In this way, the authors evaluated the functional significance of specific structural features to nacre’s overall performance, for example demonstrating convergence on similar performance for the distinct nacre architectures of different mollusk groups and a functional trade-off between nacre plate geometry and nacre toughness. The workflow opens avenues for navigating and testing optimization pathways, both for understanding evolution and performance of biological structure and application in engineering contexts to the rational design of robust synthetic composites.