3D printing revolutionizes our world with no limits to imagination and creativity. Objects of almost any shape can now be printed; patterns can easily be scaled or customized to mimic various structures. Combinations of 3D printing with other techniques have found wide applicability in various fields. Here, Wang et al. present a fabrication method which combines 3D printing with electrospinning to introduce microstructures to polymer scaffolds. These fibrous scaffolds can help to serve as a platform for tissue engineering of artificial organs.

3D printing revolutionizes our world with no limits to imagination and creativity. Objects of almost any shape can now be printed; patterns can easily be scaled or customized to mimic various structures. Combinations of 3D printing with other techniques have found wide applicability in various fields. Here, Wang et al. present a fabrication method which combines 3D printing with electrospinning to introduce microstructures to polymer scaffolds. These fibrous scaffolds can help to serve as a platform for tissue engineering of artificial organs.

After implantation of an artificially produced tissue, it is often difficult to ensure a sufficient nutrient supply of new tissue engineered construct. Ingrowth of vessels from the body induced by angiogenic factors is slow and artificially produced tissues with internal vasculature often have shortcomings such as low mechanical strength, limited diffusion or nondegrability.

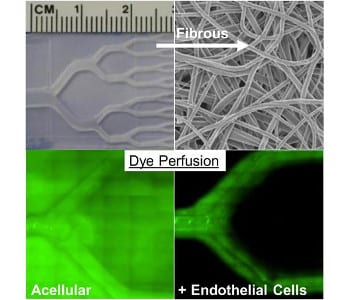

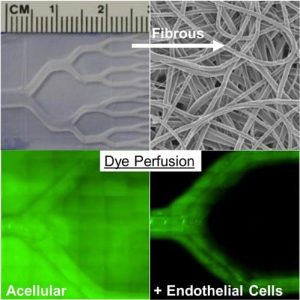

The scientists from the University of Pittsburgh, Pennsylvania address this issue by introducing a new approach. 3D printing is used to produce water-soluble poly(vinylalcohol) networks as sacrificial templates with vascular-like branching to transfer microvascular patterns to fibrous scaffolds. Endothelial cells can be grown to cover the lumen of those artificial vessels, which show reduced permeability compared to bare vessels without cells. The scaffolds are strong enough to be connected to host vessels and immediately perfused upon and they are biodegradable which makes them ideal for regeneration in tissue engineering applications.