For low-cost printed electronics applications, conductive ink formulation needs to be compatible with various patterning methods. State-of-the-art microfabrication techniques offer high resolution patterning of materials, but these methods often involve multistep processing and sophisticated, expensive instrumentation.

Direct-write technologies have been developed by many researchers, whereby day-to-day handwriting formed an important source of inspiration. A pen is a simple, yet universal, writing utensil that has been used for writing text or drawing designs on a wide variety of surfaces for centuries.

A paper published in Advanced Materials in 2011 by Professor Jennifer A. Lewis and her team titled, “Pen-on-Paper Flexible Electronics” received much attention: here, the method of using a simple rollerball pen filled with a conductive silver ink provided a low-cost portable route for fabricating conductive text, electronic art, and interconnects for light emitting diode (LED) arrays, and three-dimensional antennas on paper.

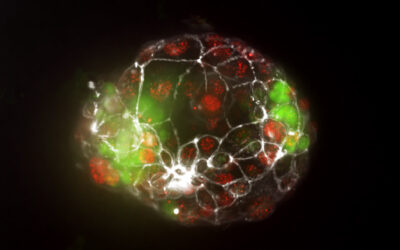

A picture of the late Professor Mildred Dresselhaus made using MXene ink as a conductive track.

Inspired by this technique Professor Yury Gogotsi and co-workers have developed titanium-carbide MXene ink, which can be used directly in pens for direct writing of conductive tracks.

Their findings are now published in Advanced Materials Technologies. Ti3C2 MXenes have shown promising results in a number of application, ranging from electrochemical capacitors to electromagnetic shielding. Unlike particle-based inks that require additional sintering steps to increase conductivity, written MXene lines can be dried at room temperature in air and achieve high conductivity. The resulting conductive features can be used for electrical circuits, or energy storage devices on a variety of substrates.

The authors of this new research predict that their results open up new pathways for printable MXene-based energy storage devices, which enable the production of inexpensive MXene devices on unconventional substrates. Translating fundamental research of new materials into finished products builds on the foundation for additive manufacturing of printable MXene devices.