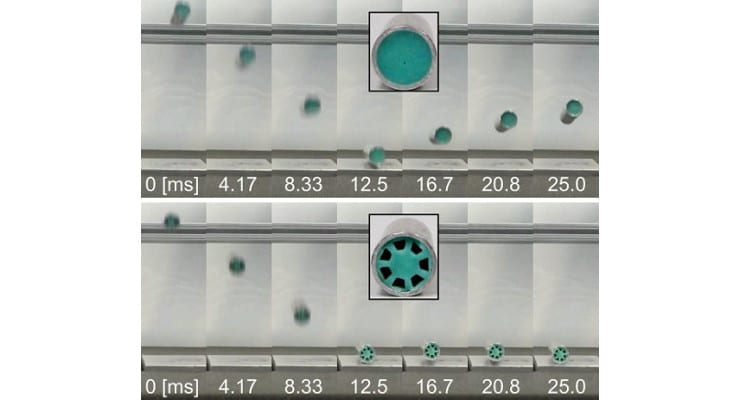

A model design for lightweight, architected material inclusions that cultivate significant and rapid impact energy dissipation in structures is investigated

A model design for lightweight, architected material inclusions that cultivate significant and rapid impact energy dissipation in structures is investigated

This special issue of steel research international is dedicated to the 250th jubilee of the foundation of Technische Universität Bergakademie Freiberg.

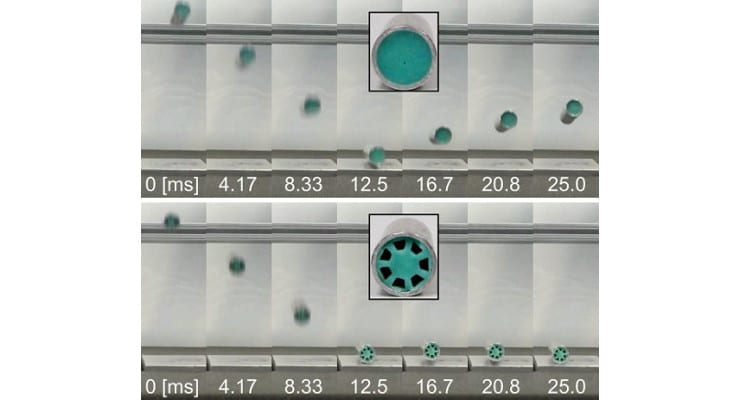

Researchers from KIT show that the strength of polymer-alumina core-shell composite microlattices doubles when their size is scaled down by 50%.

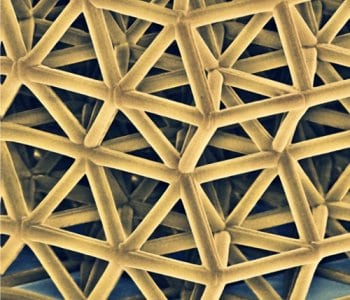

Researchers optimized then evaluated the reliability and robustness of a bioceramic manufacturing process based on the impregnation of 3D-printed mold.

From September 27th to 29th, 2016 Europe’s Material Science and Engineering scientists will meet at the MSE Congress at the TU Darmstadt, Germany.

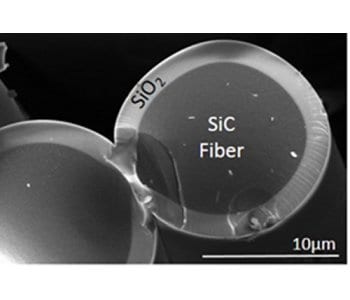

Available SiC fiber oxidation data are reviewed and oxidation rate constants, activation energies, and experimental procedures are compared.

Using a new die casting technology Power Cast and Frech reduced cycle times, saved material and improved quality.

ASK Chemicals expands its product portfolio with the addition of pre-coated sand that is used in the shell molding process.

This special section presents highlight from the collaborative research group “Adaptive surfaces for high temperature applications – the skin concept”.

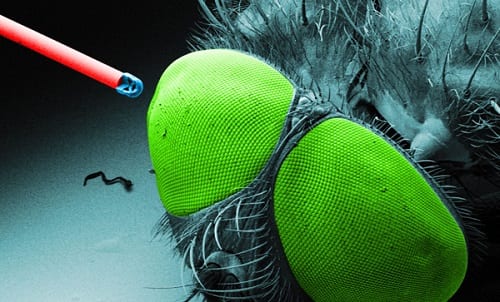

Researchers at University of Stuttgart created optical lenses which are hardly larger than a human hair.