Bags, boots, belts, and book covers—just a few of the things leather is used for in daily life. But everything has a life-span, so what happens to these leather goods when you can no longer use them?

As recycling initiatives gain momentum, it is no surprise that researchers from Nanjing Tech University, Northwestern Polytechnical University, and Sichuan University have devised a simple and scalable method for repurposing old leather as multifunctional electronic skins (e-skins).

E-skin is an artificial skin-like material with the purpose of mimicking human skin. E-skins are used to sense an external stimulus and convert it into analog electrical signals, finding potential in artificial intelligence, medical diagnostics, and prosthetics.

To date, e-skin substrates are most often based on flexible polymers. While these polymers are biocompatible and have high sensitivity, their impermeability to air limits their long-term use and comfort.

Leather, on the other hand, is the natural skin of an animal, having a sophisticated structure, flexibility, and durability. By combining leather with different functional materials, it’s properties can be enhanced beyond nature, rendering it an advanced e-skin.

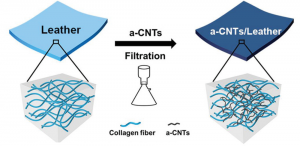

Conductive leather fabrication process: Leather is used as a filter for a‐CNTs.

The hierarchical structure of leather enables functional nanomaterials, such as carbon nanotubes (CNTs) and silver nanowires (Ag NWs), to be loaded within the structure. These mimic the sensory nerves in living skin, having the ability to detect an external stimulus and convert this into different signals.

Using leather as a filter, functional, electrically conductive nanomaterials such as acid-treated CNTs (a-CNTs) or Ag NWs, could be distributed within the hierarchical, porous leather structure (figure, left). This simple approach could be applied using other nanomaterials with different properties to produce tailored e-skins for specific purposes.

Stitching together an a-CNTs/leather e-skin and a leather patterned with interdigitated electrode arrays, a flexible, wearable pressure sensor was fabricated. Applying pressure to the material causes the a-CNTs to group together, creating greater a-CNT contact and increasing the current when applying a fixed voltage. The e-skin was shown to be highly sensitive to gentle touch, even with a feather, and showed distinctive responses to bending and torsion of the material, showing its potential for detecting other forces too.

Using the a-CNTs/leather sensor as a watchband, a human wrist pulse could be monitored in real time. This demonstration shows the potential for this sensor to be used for medical diagnostics.

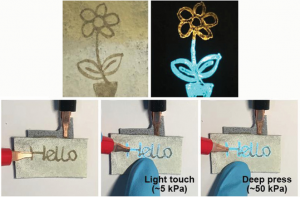

Top row: Photographs of a leather-based display before and after being turned on, respectively. Bottom row: Photographs demonstrating that brightness of the display increases as the applied force increases (left to right images).

In addition, the Ag NWs/leather could be used as the back electrode for a display when coated in an electroluminescent layer. A pen could be used to draw diverse electrode patterns (figure, right, top row). Applying pressure can cause a change in brightness (figure, left, bottom row) and generates an electrical current in the sensor.

This multitude of sensory functions of the leather-based e-skin reveals the potential for using it for intelligent robotics and medical applications.

You can read more about this smart approach for repurposing leather in Advanced Science—our open-access journal covering the hottest fundamental and applied research in materials science, physics and chemistry, medical and life sciences, and engineering.