Advanced Engineering Materials has been bringing you the latest breakthroughs in structural materials that are making those important first steps towards commercialization since 1999. With its further increased, record-high Impact Factor of 2.319 (2017 Journal Citation Reports), the journal covers a variety of key topics, such as composites, ceramics, intermetallics, and coatings, and also high-temperature, cellular, and biomedical materials, with a strong focus on new manufacturing techniques.

No access to our published content? Make sure to recommend Advanced Engineering Materials to your librarian. More information can be found here.

In this monthly feature, we highlight the research behind the artwork on the covers of the most recent issue of Advanced Engineering Materials, as well some of the most read Advanced Engineering Materials publications over the last month. The cover contributions and these top-downloaded articles are therefore currently freely accessible! Click on the titles below to get to the corresponding papers. You can find this month’s issue here. Also check out our previous Engineering Digest here.

Extreme -Value Statistics Reveal Rare Failure-Critical Defects in Additive Manufacturing

-Value Statistics Reveal Rare Failure-Critical Defects in Additive Manufacturing

by Brad L. Boyce, Bradley C. Salzbrenner, Jeffrey M. Rodelas, Laura P. Swiler, Jonathan D. Madison, Bradley H. Jared, and Yu-Lin Shen

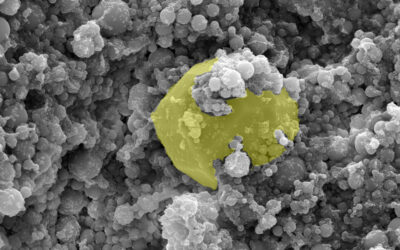

Chromium-rich oxide whiskers and nodules can form on the surface of internal pores in additively-manufactured stainless steel and act as critical defects leading to mechanical failure, as found here by Brad Boyce and co-workers from Sandia National Laboratories in Albuquerque, New Mexico, USA. This internal porosity, caused by the incomplete fusion of the source powder, results in low tensile ductility. The oxidation is thought to occur when porosity that connects to the free surface is exposed to the atmosphere during heat treatment.

A more extensive news article about this study can be found here.

Net Shape 3D Printed NdFeB Permanent Magnet

Shape 3D Printed NdFeB Permanent Magnet

by Jacim Jacimovic, Federico Binda, Lorenz G. Herrmann, Felix Greuter, Jessica Genta, Micha Calvo, Tomaz Tomse, and Reinhard A. Simon

Jacim Jacimovic and colleagues from the ABB Corporate Research Center in Baden-Daettwil, Switzerland demonstrate that 3D printing can enable the realization of NdFeB-based magnets in any desired geometry and with additional functionality such as cooling channels. Their approach can make these magnets more suitable for various applications, and at the same time less dependent on expensive rare-earth elements. This technology therefore has the capability to unlock the full potential of wind turbine generators, and boost the harvesting of renewable energy.

Inkjet and Aerosol Jet Printing of Electrochemical Devices for Energy Conversion and Storage

by L. Jay Deiner and Thomas L. Reitz

Inkjet and aerosol jet printing are emerging techniques for the fabrication of electrochemical devices, such as batteries, fuel cells, and supercapacitors, because these methods enable precise structural control over the full range of length scales that ultimately affects energy efficiency, power output, safety, and device integration. Jay Deiner from the City University of New York and Thomas Reitz from the Air Force Research Laboratory at Wright-Patterson Air Force Base, Ohio review the progress of inkjet and aerosol jet printing with a focus on electrochemical devices, and discuss future challenges towards realizing the many advantages of jet printing for energy storage and conversion.

A more extensive news article about this work can be found here.

A Review of Gold and Silver Nanoparticle-Based Colorimetric Sensing Assays

by Myalowenkosi Sabela, Sebastien Balme, Mikhael Bechelany, Jean-Marc Janot, and Krishna Bisetty

Colorimetric assays based on gold and silver nanoparticles are rapid, efficient, and sensitive, and therefore are used extensively for the detection of biomolecules and metal ions in environmental screening. In their review, Mikhael Bechelany, Sebastien Balme, and collaborators from the Université de Montpellier in France and Durban University of Technology in South Africa summarize the main parameters that influence the chemical reactions in such assays, and provide a rational classification of the current methods. Specifically, the article highlights metal ion detection through coordination with nanoparticle-stabilizing ligands, and addresses various approaches based on label-free aptamer-based sensors to better understand their role as smart colorimetric sensing devices.

Strengthening Nickel by In Situ Graphene Synthesis

by Kaihao Zhang, Matthew Poss, Ping-Ju Chen, and Sameh Tawfick

Owing to the superior strength and atomic thickness of graphene, it can in theory reinforce metals beyond the usual limitations of the rule of mixtures by constraining the motion of dislocations and strain localization at the grain boundaries. Sameh Tawfick et al. from the University of Illinois at Urbana Champaign show that strengthening nickel by in situ graphene synthesis is a simple yet effective process to fabricate metal-graphene composites having both strength and toughness exceeding the average properties of the constituents. Their nickel-multilayer graphene composite exhibits superior mechanical and electrical properties in comparison with any reported metal matrix composite so far.