A lightweight, high-strength titanium material has been engineered that could lead to stronger medical devices and innovative vehicle and spacecraft designs. The research team used a common titanium alloy, Ti-6Al-4V, to construct the “metamaterial”, a term used to describe an artificial material that possesses unique properties not observed in nature — meta means “beyond” in Greek.

Many such intricate and surprisingly strong structures do exist in nature, like that of the Victoria water lily. Native to South America, this gigantic floating leaf is strong enough to support an adult owing to the unique lattice structure of it veins.

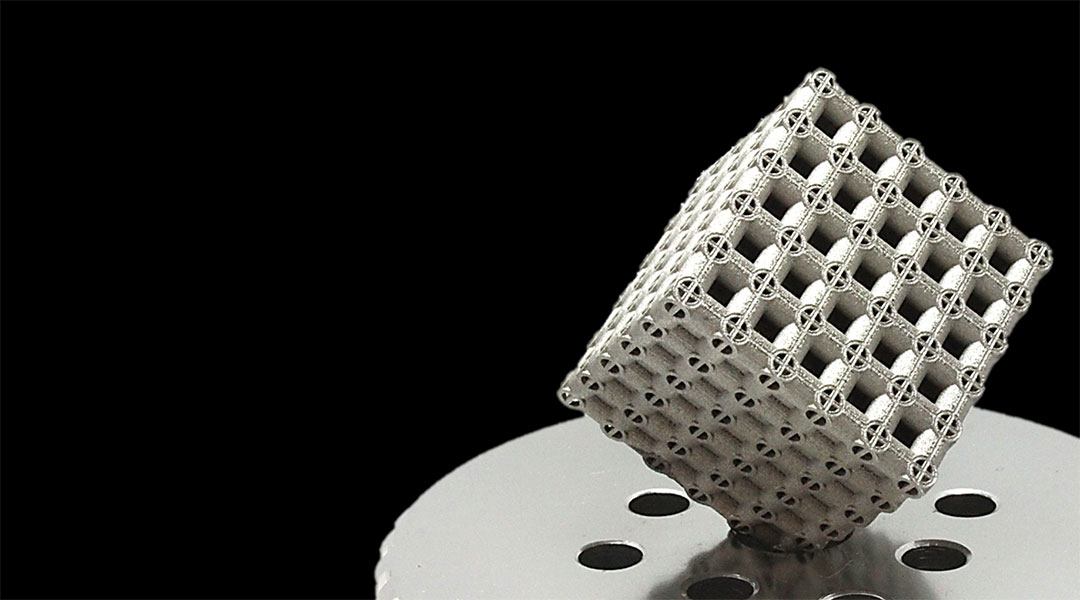

The structures of manmade materials can be designed to mimic these plants and other natural porous materials like coral, with different lattices that range from simple cubes to complex dodecahedrons. The pores in these lattice structures interconnect, forming channels. Known as “cellular” materials, these lattice materials often come with a strength tradeoff if not designed properly, according to the RMIT researchers.

“However, metal 3D printing is a game changer, allowing researchers to design and fabricate highly innovative light and strong cellular metals,” said Jordan Noronha, a Ph.D. candidate who worked on the project at RMIT.

In cellular materials, lattices are connected in three dimensions by thin, solid rods or beams called struts. By using hollow struts instead, the researchers aimed to make a low-density cellular material just as strong as a solid metallic alloy with a similar density to high-strength magnesium alloys.

Printing the metamaterial

The research team led by Ma Qian, a professor at RMIT’s Center for Additive Manufacturing, used a 3D printing process called “laser powder bed fusion” to fabricate the titanium metamaterials. This technique, which constructs a material layer by layer using a high-powered laser beam, is commonly used to prepare complex manufacturing parts from less than a millimeter up to nearly two meters in size.

Qian explained his team’s approach. “First, the entire lattice metamaterial sample is designed as a digital model. Then, this model is digitally sliced into many thin layers using a software tool.”

“This layer-based fabrication process involves laser melting of metal powders, rapid solidification of the liquid metal (the melted metal powders) and repeated heating and cooling processes of the solidified metal,” he elaborated.

Qian says the entire process currently takes around 18 hours, but through optimization, he and his team plan to shorten the time frame in the future.

What makes the material so strong?

Hollow struts and thin plates are the two topologies responsible for the metamaterial’s high strength. Unlike most cellular materials, which contain weak points where stress concentrates, these two complementary lattices evenly distribute stress while providing support.

“Ideally, the stress in all cellular materials should be evenly spread,” Qian explained. “However, for most topologies, it is common for less than half of the material to mainly bear the compressive load, while the larger volume of material is structurally insignificant.”

“This multi-topology design also promotes the deflection of crack paths to enhance the toughness,” he added. “Instead of the cracks occurring directly through the lattice, which occur in most cellular materials, in our thin-plate hollow-strut lattice topology, the struts and plates work together to divert the cracks along a longer path.”

Magnesium alloys are currently used in commercial applications that require high strength and light weight. Compared with the strongest cast magnesium alloy available (WE54), a sample of the titanium metamaterial with a comparable density is much stronger. Magnesium alloys are also not amenable to laser powder bed fusion or 3D printing owing to vaporization of the powder, giving the titanium alloy a manufacturing advantage.

Next steps and potential applications

Before the material is commercialized, Qian and his team first want to ensure that the material performs at its maximum efficiency.

To do this, they plan to improve their current design to strengthen and lighten their titanium metamaterials even more. For example, based on numerical simulations, they will adjust the proportion of thin plates to hollow struts to allow a more uniform stress distribution throughout the entire structure.

According to the researchers, if the metamaterial is fabricated from a high-temperature titanium alloy, it can be used at temperatures up to 600°C. This feature, along with its corrosion resistance, makes the material suitable for use in high-speed flying aircraft or missiles, which must be able to withstand the intense heat generated by their high speeds. Titanium drones used to closely monitor or fight wildfires would also benefit from the light weight, strength, and heat-resistance of the metamaterial.

Because the metamaterial is also biocompatible, it could also be used in medical devices such as bone implants. But the technology is not yet widely available at this stage, so its adoption by industry might take some time. “Our most important limitation is the exclusivity of our technology, and the cost of fabrication could be another important concern,” Qian stated.

“Traditional manufacturing processes are not practical for the fabrication of these intricate metal metamaterials, and not everyone has a laser powder bed fusion machine in their warehouse,” he added. “However, as the technology develops, it will become more accessible, enabling a larger audience to implement our high-strength multi-topology metamaterials in their components.”

Reference: Ma Qian, et al., Titanium Multi-Topology Metamaterials with Exceptional Strength, Advanced Materials (2023). DOI: 10.1002/adma.202308715