Haoshen Zhou took a moment to outline the challenges for researchers interfacing electrodes with solid electrolytes. For more comprehensive information on this issue, you can also check out his recent Excellence in Energy review, ‘Rechargeable Solid-State Li–Air and Li–S Batteries: Materials, Construction, and Challenges’, in Advanced Energy Materials.

Do we know what causes the large resistance observed at the electrode/solid electrolyte interface?

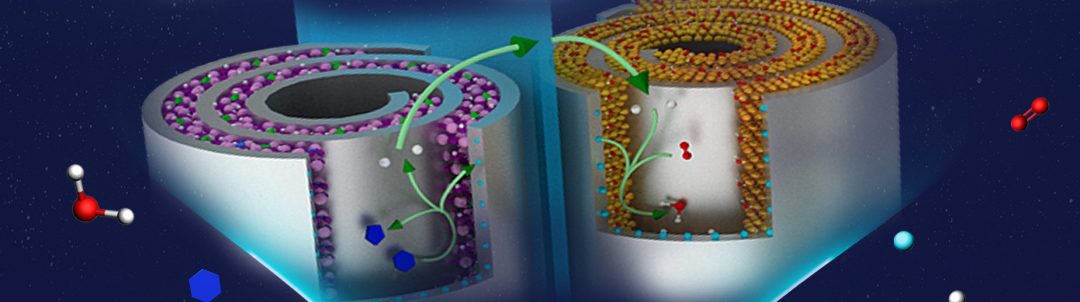

Generally, Li ions crossing the electrode/solid electrolyte interface need more energy to overcome the energy barrier than when they’re passing through the electrode or the solid electrolyte, which indicates a large interfacial resistance. In fact, both physical and chemical instabilities between the electrode and solid electrolyte materials should be taken into consideration. The physical instabilities generally consist of a crystal lattice mismatch and a lack of wettability. A lattice mismatch commonly exists between intercalation-positive electrodes such as LiCoO2 or LiMn2O4 and solid electrolytes, especially oxide electrolytes, while the lack of wettability is more prominent with Li anodes and solid electrolytes. Lattice mismatch and a lack of wettability lead to separation or poor contact between the electrode and the solid electrolyte. In addition, if the solid electrolyte is chemically unstable in the presence of the electrode materials, a layer composed of the side reactants will form, which is detrimental to lithium ion transport.

What problems does this create for solid-state battery systems?

For a solid-state battery, the large interfacial resistance may increase the whole resistance of the battery, leading to a poor energy efficiency. Besides this, the interfacial contact may become worse because of the physical/chemical instabilities between the electrode and solid electrolyte, which is harmful to its long-term practical application.

How close are we to solving this issue?

A variety of methods have been adopted to improve interfacial contact and reduce the interfacial resistance. For example, a germanium thin film was introduced as an interfacial layer between a Li anode and LAGP solid electrolyte, which not only improved interfacial contact, but also protected the LAGP from chemical reaction with Li. In addition, the surface structure can be modified to obtain intimate contact between the electrode and electrolyte. For example, a porous solid electrolyte surface has a higher contact area than a planar surface, and a lower interfacial resistance with the electrode is observed. Solid electrolyte surface engineering and interfacial film coatings provide great prospects for the practical application of solid-state batteries.

Are you working on solid electrolytes, or find yourself interested in critical problems in energy research? Try these:

- Energy Perspectives: Arumugam Manthiram Describes Polysulfide Shuttling

- Energy Perspectives: Qiang Zhang Outlines Lithium Dendrite Formation

- Emerging Technologies, Markets and Commercialization of Solid Electrolytic Hydrogen Production

- World’s Smallest Transistor Goes Solid-State

Have you already discovered the Excellence in Energy series? Check out this virtual issue of invited-only reviews from top energy researchers. Everything is free to read for a limited time.