Engineers have developed tactile sensors with increased sensitivity, thanks to auxetic mechanical metamaterials.

Tactile sensors are common amongst technologies such as touchscreens, touchpads, smartwatches, and fitness trackers. These sensors convert physical stimuli, such as pressure or force, into an electrical response within the device. Beyond consumer electronics, tactile technology is highly relevant for advanced prosthetics, industrial robotics, security systems, and healthcare devices that give feedback on the users’ physical movements for health monitoring.

Mechanical metamaterials (MMs) have gained popularity for building tactile sensors and actuators thanks to the tunability of a wide range of their physical properties. These can be introduced by tweaking their periodic cellular architectures to concentrate or amplify the pressure applied to the sensor.

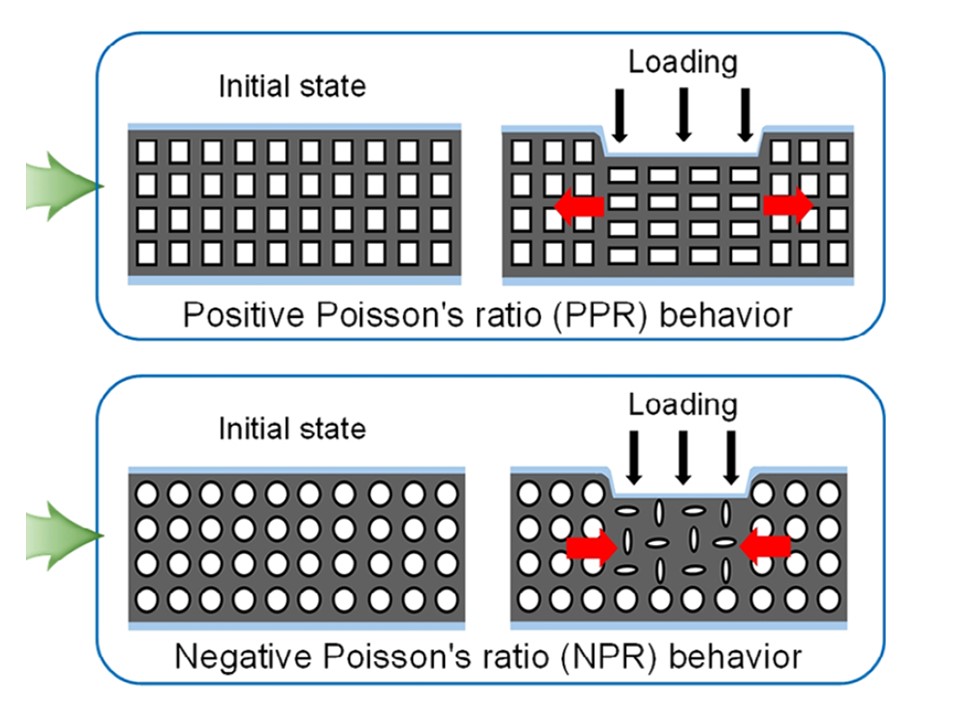

and a negative Poisson’s ratio material. Image credit:

Mingyu Kang et al., doi.org/10.1002/adfm.202509704.

Interestingly, a category of MMs called auxetic mechanical metamaterials (AMMs) exhibits negative Poisson’s ratio, i.e., when compressed, they tend to contract laterally instead of expanding. Prof. Soonjae Pyo’s team at Seoul National University of Science and Technology used digital light processing, a 3D printing technique for curing photopolymerizable materials layer-by-layer, to develop silicon rubber-based AMMs comprising specifically arranged spherical voids in a cubic lattice. The joints around these spherical voids facilitate the above-mentioned lateral contraction as they tend to undergo rotational deformation under applied stress.

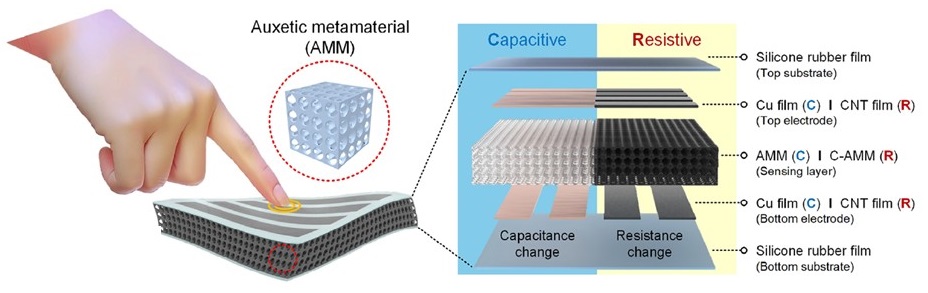

The team built two kinds of tactile sensors based on such AMMs: capacitive sensors, that respond directly to pressure modulation, and a carbon nanotube (CNT)-coated resistive sensor (C-AMM) that responds to changes in resistance in a material when deformed. A capacitive sensor is typically more sensitive to small changes in pressure, while a resistive sensor is favorable for detecting larger pressures, thereby complementing each other.

Exploring a possible real world application, the team developed a resistive sensor by creating a sensor array, wherein 16 C-AMM units are arranged in a grid of 4 rows and 4 columns each, creating a 16-pixel grid, each integrated between custom-built electrodes.. Such an array was subjected to varied levels of stress from non-contact to multiple points to assess its sensitivity and spatial discrimination. Further, the researchers developed a smart insole comprising a pair of electrodes and C-AMM sensor arrays sandwiched inside polymeric films, which they installed in shoes for gait monitoring and pronation analysis while the user is out for a walk.

This research offers what the authors call a “structure-centric design approach, decoupled from specific material choices,” which can serve as a strategy for building customized tactile sensors capable of better strain concentration and energy dissipation for the improved sensitivity of prosthetics, biomedical devices for health monitoring, and extending the capabilities of robots.

Featured Image Credit: Gordon Johnson via Pixabay