Initiated chemical vapor deposition (iCVD) is a promising platform technology to deposit functional polymer for the extension of application ranges and development of diverse devices. The deposition of polymer thin film by this iCVD technique serves as a versatile tool for the synthesis of functional polymers directly from monomers in vapor phase.

iCVD is a polymer deposition process whereby both polymer synthesis and film formation occur simultaneously on the surface of the substrate. This one-step fabrication method successfully achieves surface modifications without changing bulk properties of the substrate, rendering the process favorable for biological and electronic applications.

Substrate surfaces can be functionalized directly from the iCVD polymer film or can selectively gain functionality through chemical reactions between functional molecules and conjugate reactive groups on the substrate surface provided by the functional iCVD polymer films. The additive-free, solventless process warrants the unprecedentedly high purity of the polymer film.

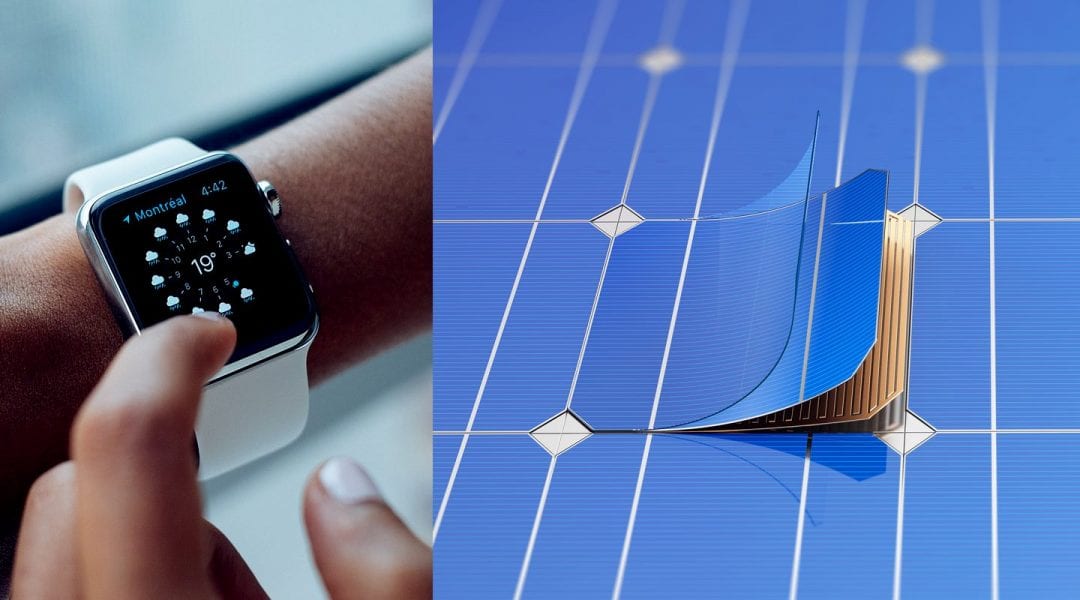

Unlike the solution-based process, the excellent conformal coverage characteristics enables the utilization of the iCVD process for the conformal surface modification of non-conventional substrates with various kinds of nanostructures thereon, such as membranes, paper, fabrics. These beneficial aspects of iCVD could spur on breakthroughs in device fabrication based on the deposition of robust and functional polymer thin films.

The iCVD method has progressed significantly in the last decade in the field of surface engineering by striking a strong balance between device performance and operational simplicity. The exploitation of fabrication methods for the integration of new materials into devices contribute to the main advantages of device design and performance. Thus, the deposition of thin polymer film via iCVD will be a pivotal stepping stone to the development of the next generation of surface engineering applications. A review published in Advanced Engineering Materials describes significant implications of and recent progress made in iCVD-based technologies in three fields: electronic devices, surface engineering, and biomedical applications.