The demand for electronic monitoring devices in fields such as food quality assurance and healthcare is experiencing significant growth. Examples of this emerging digital revolution include temperature-, pH-, and gas-monitoring labels for food spoilage prevention, smart pills for gastrointestinal tract observation, and remotely controlled systems for targeted drug delivery. A shared consideration across these applications is the direct or potential interaction of such devices with the human body. One way to partially address the presented safety challenges is to use ingestible systems, using non-toxic and sustainable materials to help integrate these technologies into routine healthcare practices.

Edible electronics represent a rapidly advancing area that intersects materials science, biomedical engineering, food technology, and sustainability, and may facilitate sensory and control functions within future edible robotic systems.

Recent progress in edible electronics includes the development of edible batteries composed of riboflavin and quercetin, utilizing water-based electrolytes capable of powering small diagnostic and therapeutic ingestible devices. Edible sensors made from components such as honey, gold leaf, and food pigments enable pH and frequency sensing. There are other simple, straight-forward applications; however, more complex operations—including control, computation, and synchronization—necessitate standalone devices. Core to this advancement will be logic gates (such as NOT, NAND, XOR, etc.), which perform Boolean operations and can be integrated to create circuits supporting trigger signals and combinational or sequential logic tasks. These form the basis for printed, edible, integrated circuits with computational functionality in applications such as gastrointestinal monitoring capsules, intelligent food labels, and edible robots.

Prof. Mario Caironi of the Istituto Italiano di Tecnologia in Milan is at the forefront of edible electronics research, leading distinguished European initiatives such as the Electronic Food Project and ROBOFOOD. His team’s recent work demonstrates the feasibility of edible electronic circuits by integrating batteries with logic circuits made exclusively from ingestible materials, ensuring complete digestion, without generating e-waste.

Their circuit design utilizes a co-planar architecture on a substrate of ethyl cellulose, an approved food additive (E462). Interdigitated electrodes are inkjet-printed using a water-based gold ink, with another food additive, shellac ink (E904) serving as the passivation layer. The semiconductor applied is P3HT, a biocompatible polymer with no documented cytotoxic effects, and chitosan is used as the electrolyte. These devices, compatible with 0.7 V edible batteries, generate currents in the microampere range, which is within established tolerance limits. The demonstrated logic family includes NOT and NAND gates, as well as a ring oscillator operating at frequencies up to 1.32 Hz.

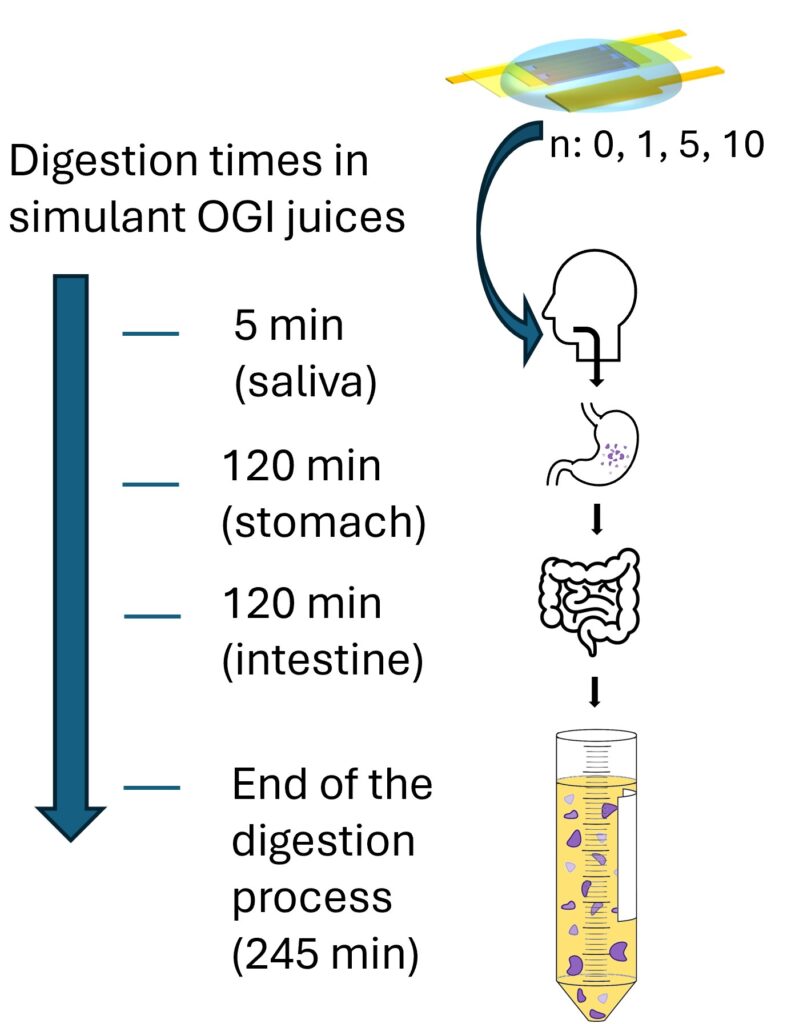

All materials are present in quantities significantly below toxicity thresholds; however, the frequency and dosage of device ingestion should be carefully determined to ensure digestibility. Preliminary studies utilizing simulated oro-gastrointestinal conditions and examining digestion products indicate no observable alterations to the intestinal cell epithelium.

Although further toxicity and safety investigations are required, this advance highlights the potential scalability and future integration of standalone edible electronics.

Featured Image: OpenClipart-Vectors via Pixabay