Coming up with a way to predict the functional properties of new materials would save on raw materials and cut out a lot of hit-and-miss lab work. A new model attempts to do just this, applying the power of computational intelligence (a form of artificial intelligence) to match experimental parameters with desired functional objectives.

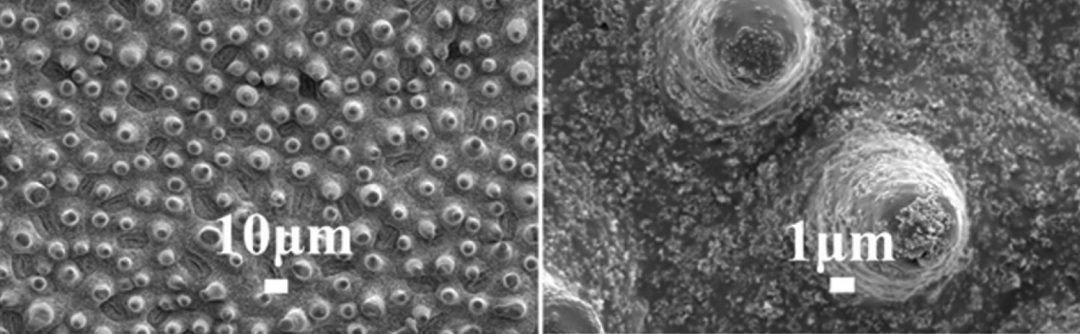

These structures generate superhydrophobicity on natural surfaces such as the lotus leaf. Can artificial intelligence optimize the experimental parameters to ideally copy the functions of these structures in the laboratory?

A research team working in China and the UK has combined artificial neural networks and evolutionary computation to generate the model, and then applied it to determine the parameters required to form self-cleaning, superhydrophobic surfaces.

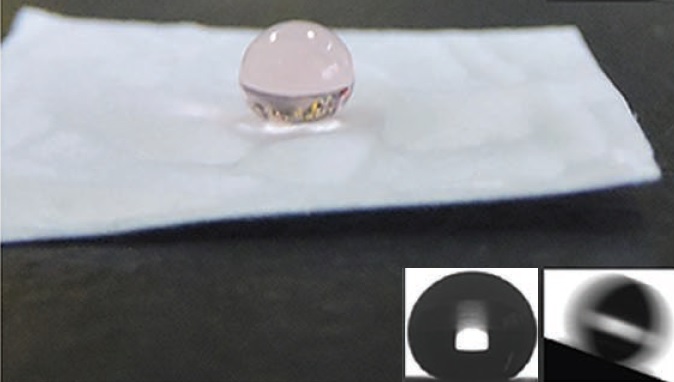

They started by defining the parameters relevant to the characterization of such surfaces, including adhesive forces, water contact and sliding angles, and aspects of the morphology affecting how water droplets bounce across a surface during self-cleaning. These were denoted the ‘objectives’—the goals that the model should set out to achieve by tuning the experimental parameters. The latter were defined as the “degree of nanostructure within the hierarchical surface morphology, water droplet volume, and the distance that the droplet or the surface travels when measuring the adhesive force.”

The researchers also set some specific targets for their objectives; in particular, they note that the water contact angle of a self-cleaning surface needs to be over 150 degrees.

Certain relationships, such as the exact influence of water droplet volume on the measurement of sliding angles, could be better understood by using this model: it aids in mapping out the degree of influence each parameter has on each objective. Due to the complexity of these relationships and the imperfect reproducibility of experimental conditions, this is much more difficult to do in the laboratory.

This is a lot of promise. So how did the model measure up when compared to traditional manual labor?

Polyvinyl chloride (PVC) with varying SiO2-nanoparticle content was used to form biomimetic superhydrophobic surfaces, and computational intelligence was applied to analyze the data and generate the model, and then to optimize all parameters. “The obtained optimal parameters are consistent with the experimental observations,” claim the authors, who suggest that only small datasets are required to accurately tune the model—another advantage of their technique.

For the details of this model, see their Full Paper, freely available for all to read in Advanced Science.

Interested in the current applications of AI? Cast your eye over these articles: