In comparison to electrospun fibers with a smooth surface, secondary nanostructures inscribed onto hierarchical fibers provide additional dimensionality for tuning the surface and physicochemical properties of materials. In the past years, nanoporous and nanowrinkled fibers have been produced by simply tuning processing parameters such as solvent, humidity, composition, etc. Often, however, secondary nanostructures like nanorods and nanokebabs are deposited through either the solution growth of nanostructures or the solution crystallization of polymers. However, uniformly depositing such nanostructures onto all fiber surfaces is challenging due mainly to the restricted diffusion of polymeric solutes underneath the top few layers. Consequently, creating structural hierarchy in thicker fiber mats or even in composite fibers is still a demanding task.

In comparison to electrospun fibers with a smooth surface, secondary nanostructures inscribed onto hierarchical fibers provide additional dimensionality for tuning the surface and physicochemical properties of materials. In the past years, nanoporous and nanowrinkled fibers have been produced by simply tuning processing parameters such as solvent, humidity, composition, etc. Often, however, secondary nanostructures like nanorods and nanokebabs are deposited through either the solution growth of nanostructures or the solution crystallization of polymers. However, uniformly depositing such nanostructures onto all fiber surfaces is challenging due mainly to the restricted diffusion of polymeric solutes underneath the top few layers. Consequently, creating structural hierarchy in thicker fiber mats or even in composite fibers is still a demanding task.

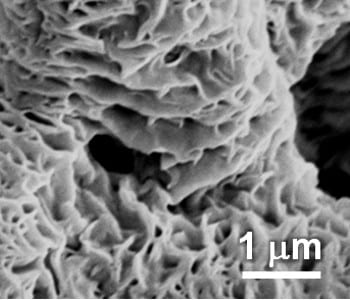

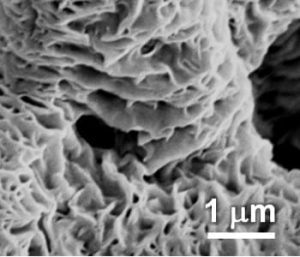

Now researchers have demonstrated that a simple solvent vapor annealing (SVA) treatment can effectively inscribe secondary nanostructures onto polycaprolactone (PCL) and PCL-based composite fibers. In this report, Bingbing Li, a chemistry assistant professor at Central Michigan University and her graduate students, Jianzhao Liu and Adam J. P. Bauer, discovered that when the PCL fibers are annealed in acetone vapor, “free” amorphous chains can be selectively mobilized, while the integrity of the crystalline region remains intact. The delocalized amorphous chains redeposit themselves onto the pre-existing crystal edges, giving rise to striking secondary nanostructures inscribed onto the neat PCL fibers and the PCL-based composite fibers. The efficacy of such SVA treatment relies on the availability of de-localizable amorphous chains and is therefore correlated to the crystallinity of the semicrystalline polymers.

It is worth noting that numerous PCL-based systems have been electrospun into smooth fibers, which have been and are still being heavily studied not only for fundamental interests but also for biomedical applications. The reported method can therefore be adapted to generate structural hierarchy for neat PCL fibers with various fiber diameters, core/PCL-shell fibers, PCL-based blend fibers, PCL-based composite fibers, and PCL-based drug-loaded fibers. By choosing suitable solvent vapor and experimental temperature, the SVA method reported here could be also applied to other semicrystalline polymer-based systems. Thus, the reported simple and effective one-step SVA approach provides significant new insight into the design and fabrication of structurally hierarchical polymeric materials.