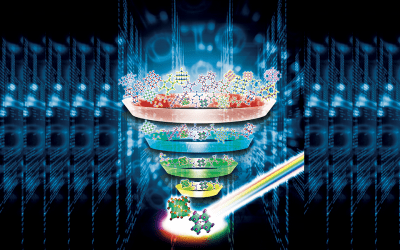

Laser cutting allows a highly efficient processing of complex metal parts. Compared to conventional machining methods, the non-contact laser process minimizes both the machining time due to lack of set-up time and the costs caused by tool wear.

With a repeat accuracy of up to 50 μm and also highest dynamics, Jenoptik’s new laser cutting machine Votan ranks among the most precise systems in its class. According to the German based company, due to its design and high flexibility, Voltan is a virtually wear-free tool able to process a variety of metal working parts. In just one second, it cuts a circle or other standard contour. This allows for a significantly shorter cycle time compared to other robot systems.

Non-contact laser tooling minimizes both the machining time due to lack of set-up times and the costs caused by tool wear. Source: Jenoptik AG

The system concept of this series is based on a beam guide inside the robot. Thus, laser sources with a power of up to 5 kW can be used without the necessity for a complex external beam guide, as Jenoptik reports. At the same time, the equidistant beam path prevents the laser beam from pumping effects, ensuring a stable beam quality. With this approach the company intends to provide customers with a technological competitive advantage.

With its metal cutting laser machine series, Jenoptik serves the automotive industry by cutting e.g. complex car body and structural parts as well as hydroformed tubes used for exhaust systems or car body rail manufacturing.