Flexible electronics have emerged in recent years, and show applications in many fields, such as sensors, photovoltaics, paper-like displays, soft robotics and wearable electronics. Among the many properties, the most important property for the materials such applications is that they need to be non-brittle and flexible. Because in rigid materials bending or folding otherwise results in a broken device.

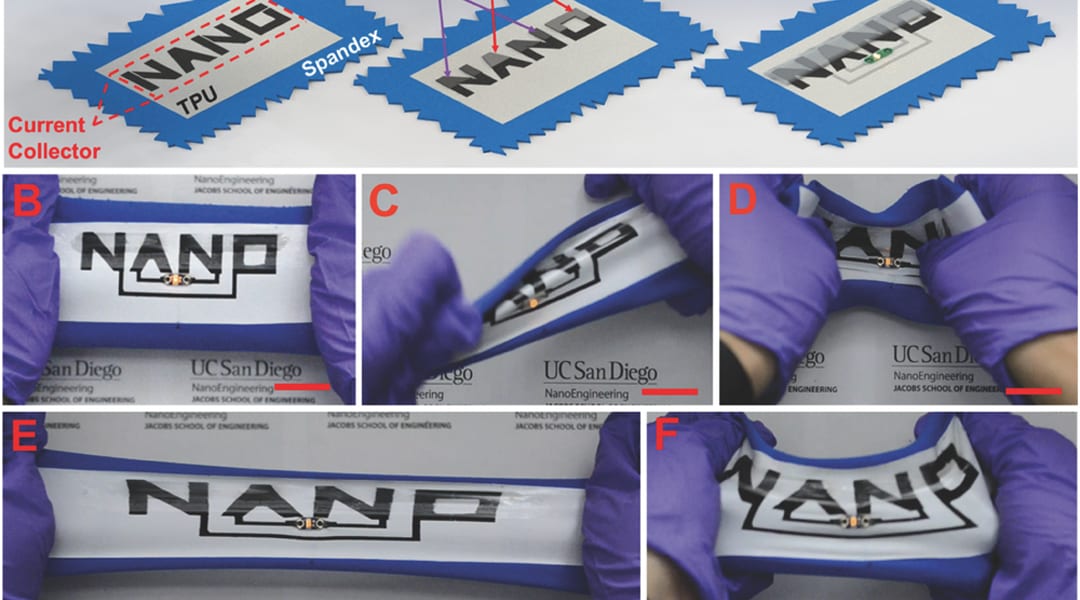

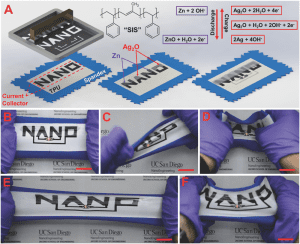

Strategy for all-printed Zn-Ag2O battery on a stretchable textile and photographs of sealed battery while being stretched, twisted and indented.

In order to power wearable devices, flexible batteries are required. Although some reports show intrinsically stretchable batteries, none are completely built on elastic systems. The cycle ability, current density, or areal capacity of these batteries are compromised when a rigid component undergoes a large physical strain. Furthermore, these batteries are not economical because they rely on lithographic, spray/dip coating, or “cut-and-paste” fabrication routes that are extremely expensive and have a low throughput.

Prof. Joseph Wang and colleagues from the University of California San Diego, USA, have now reported in their paper in Advanced Energy Materials the first all-printed stretchable zinc-silver oxide rechargeable battery using cost-effective screen printing of highly elastic, conductive inks.

By formulating a new elastic binder that contains a long polyisoprene chain and short polystyrene ends, this functional polymer has both elastic and simple processing properties compared to common elastomers. In contrast to common elastomers, in this approach an additional curing (vulcanisation) step is not needed to form a 3D cross-linked network and to form truly elastic behaviour. The resulting Zn-Ag2O battery demonstrated a reversible capacity density of 2.5 mAh.cm-2 even after multiple iterations of 100% stretching.

Using this unique block polymeric structure as electric binder, the reported approach has the potential to outperform previous printed, stretchable electronics and is expected to pave the way to enhance other forms of energy storage technologies, including Li-ion batteries, supercapacitors, and photovoltaics toward self-power stretchable electronics. Furthermore, these printed devices would allow several degrees of freedom relevant to the wearer’s movement, and can be conformably utilised in diverse real-life situations.