The separation of emulsified water and oil mixtures is a key challenge for the environment. The extraction of oil often requires the injection of superheated steam into the ground, and while this approach is immensely successful in recovering oil, the emulsions thus created can be difficult to separate. The cleanup of oil spills further requires the development of technologies that can readily separate water from oil.

The separation of emulsified water and oil mixtures is a key challenge for the environment. The extraction of oil often requires the injection of superheated steam into the ground, and while this approach is immensely successful in recovering oil, the emulsions thus created can be difficult to separate. The cleanup of oil spills further requires the development of technologies that can readily separate water from oil.

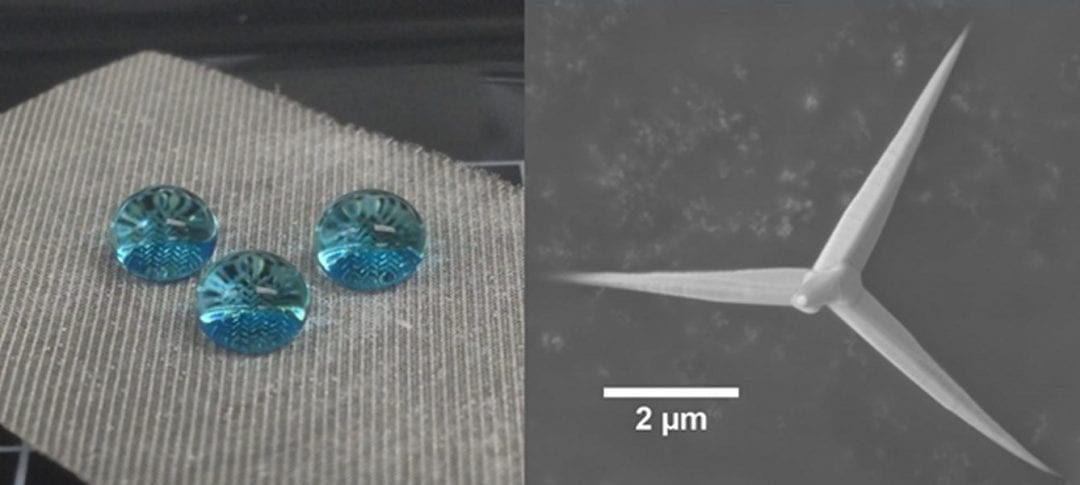

Sarbajit Banerjee et al. from Texas A&M University developed a robust inorganic system capable of handling the extreme heat and wear typical of oil extraction that engineers complete separation of water and oil. Utilizing a stainless steel mesh substrate embedded with ceramic ZnO tetrapods that constitute “spike strips”, a highly textured surface is obtained that strongly repels water but allows for permeation of oil.

Very much like a caltrop, the tetrapod morphology ensures that there is always at least one pointed end facing away from the substrate, towards the flowing liquid, and thus ensures its ability to interact with the liquids. With many of these nanostructures arrayed onto a surface, the sharp arms form a “bed of nails” thus repelling water due to its high surface tension, while allowing oil to pass through the membrane. An adhesive layer ensures that the tetrapods remain anchored onto the stainless steel meshes. The design and demonstration of high-efficiency separation of water and oil, even at high temperatures, paves the way to largescale applications of such systems in oil extraction, food processing, environmental cleanup, and fluid handling in complex environments such as automotive and aerospace industries.