Biomedical implants often require surgical implantation and extraction. These procedures add significantly to the health risks associated with using these electrical devices. If a temporary implant could be designed to safely degrade in a controlled manner, a second surgical intervention for implant removal would be avoided.

Such an electronic device would need to have very specific properties. It would need to be readily broken down by enzymes, it would need to be hydrophobic so as to avoid swelling, and both it and its degradation products would need to be non-toxic. Given these constraints, a team from the USA has proposed that wax might be a good candidate material.

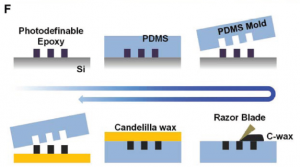

Schematic of the production process for wax electronics.

The team performed an extensive suite of studies on various forms of wax to determine their suitability. The wax that showed the most promise was sourced from a shrub native to north America, called candelilla. Films made with this wax were implanted under the skin of four rats for a period of 3 months, and were observed to degrade in a predictable manner.

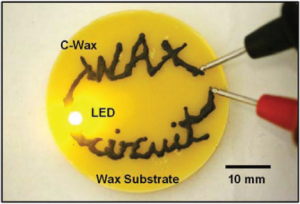

With a good candidate for biodegradable electronics in hand, the team then demonstrated that candelilla wax loaded with tungsten nanoparticles could serve as a conductive material. The image below shows a candelilla wax circuit on a wax substrate, enabling the powering of an LED.

The wax based circuit in action.

Finally, to examine the potential health impacts of both candelilla wax and the conductive wax/nanoparticles mixture, the weight gain and immune responses of mice implanted with the materials were measured. Neither had a significant impact on these parameters, suggesting that these materials are indeed biocompatible.

Unfortunately, thick wax samples were found to be susceptible to cracking: a process that can affect device performance. Studies are currently underway to design related materials that avoid this mechanical defect. With these limitations in mind, this preliminary work certainly shows promise for applications in the field of biodegradable medical implants.