Lasers have become indispensible for materials processing in science and industry. Aside from the classical Gaussian intensity profiles, unconventional laser beam shapes open up new perspectives for technologically relevant areas such as deep-hole drilling, photopolymerization, and nanopatterning.

Lasers offer a highly directional and localized source of energy that facilitates materials modifications at precise locations. The typical laser parameters that are controlled in materials processing include energy, fluence, spot size, wavelength, polarization and, in the case of pulsed lasers, pulse duration and repetition rate. The control and influence of the laser beam shape is less common – although it offers interesting benefits.

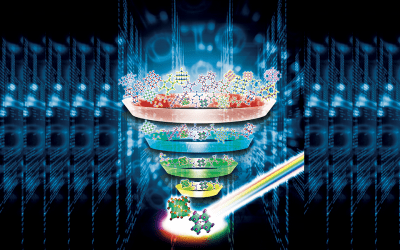

The shape of a laser beam is defined as the irradiance distribution of the light when it arrives at the material of interest. Most commercial lasers provide either a Gaussian intensity profile, a “Top-hat” intensity profile, or are modified to fall into one of these two categories. However, there are non-conventional beam shapes, such as Bessel, annular, and vortex beams that enable novel approaches to modifying materials. In a review paper, Marti Duocastella and Craig B. Arnold from Princeton University (USA) discuss properties, generation methods and emerging applications for such nonconventional beam shapes.

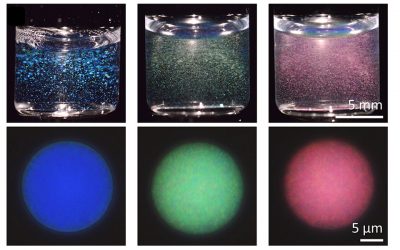

Bessel beams appear as a series of concentric rings. Annular beams, also called doughnut-shaped beams, show an intensity distribution concentrated in a ring with no on-axis intensity. Optical vortex beams are defined as a beam whose phase varies azimuthally along the direction of propagation.

The “non-diffracting” behavior of Bessel beams results in a long depth of field, which can be used to increase the tolerance of the focal plane position during material processing. This allows for the creation of uniform features over non-planar or uneven surfaces without the need to adjust the relative position of the sample and focus as with shorter depth of field beams. Such a long depth of field also makes Bessel beams suitable for producing high aspect ratio structures, such as long channels in transparent materials or polymerized fibers, without scanning the beam inside the material or otherwise translating the sample. The self-healing property of Bessel beams – they reconstruct after an obstruction – can help to mitigate effects of debris and other products of the laser processing that can partially block incident beams.

Similarly, annular beams have advantages for creating novel structures in materials, improved micromachining and deephole drilling, and reducing the feature size in multiphoton polymerization. The related vortex beams can induce unique light-matter interactions leading to enhanced ablative processing.

Novel and cost-effective methods to generate these structured beams have opened a new chapter in fundamental laser-matter interactions, enabling unique material responses with control down to the nanoscale, and have the potential to revolutionize the way lasers are used for processing.