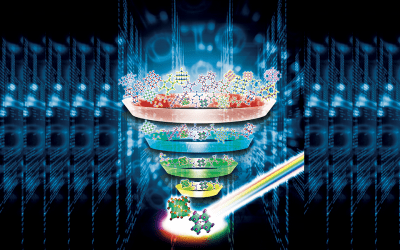

Schematic diagram of the sensor structure, comprised of a transparent glass layer, a microfluidic region and a PC surface for fluorescence enhancement

The enhancement of a liquid-based homogenous fluorescence assay has been achieved by using the resonant electric fields from a photonic crystal surface. Key to success is an integration of the nanostructured surface and a submicron fluid channel fabricated by E-jet patterning.

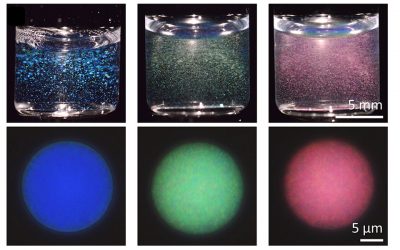

Fluorescence is the most widely used detection technique in life science research, disease diagnostics, and genomic/proteomic research tools. Surface-based fluorescence assays have achieved sensitivity gains of over two orders of magnitude by performing the assay protocol upon a nanostructured surface that is capable of enhancing the fluorescence excitation intensity of surface-bound fluorophores and by enhancing the collection efficiency of emitted photons. One of these techniques is photonic crystal enhanced fluorescence (PCEF). It utilizes high quality factor resonances from a periodic dielectric surface structure to achieve high surfacebound electric fields that do not quench fluorescence emission.

However, many important classes of fluorescent assays, such as Fluorescence Resonant Energy Transfer (FRET) assays have to be performed in a “homogeneous” format, with all assay components in a liquid environment, not coupled to a surface. If such a homogeneous assay shall be enhanced by application of nanostructured surfaces, it has to be considered that the enhanced electric field is tightly confined to the surface, with an evanescent field volume that extends only 100–600 nm into the liquid media. As a consequence, the liquid volume has to be confined so that a substantial proportion of it will reside within the evanescent field volume – by integration of the nanostructured surface and a fluid channel with a submicron height dimension. However, so far used production techniques either are low throughput, offer poor surface adhesion strength, or poor control of channel dimensions.

A research team at the University of Illinois at Urbana Champaign (USA) now suggests an electrohydrodynamic jet (e-jet) printing approach to produce such an integrated device. E-jet printing is a cost-effective, highly controllable and very simple nano-manufacturing process. It uses electric field-induced fluid jet printing through micron-scale nozzles to achieve nanometer to micrometer-scale droplet placement accuracy and accurate control of ~0.5 pl dispense volumes.

The researchers used a UV-curable optical adhesive to print a pattern upon the PC fabricated on a silicon substrate, attached a glass cover with pre-drilled inlet/outlet holes to the PC surface, and cured by a short exposure to UV light. They were able to produce channels of arbitrary shape with micrometerscale precision of lateral dimensions. The PC was excited by a custom-designed compact instrument that illuminated the PC with collimated light that precisely matched the resonant coupling condition when the PC was covered with aqueous media.

To prove their concept, the team used a molecular beacon nucleic acid FRET probe for a specific miRNA sequence. They achieved an enhancement of factor eight of the fluorescence emission signal.

The scientists are convinced that their novel approach may be utilized for any liquid-based fluorescence assay for applications in point-of-care diagnostics, environmental monitoring, or pathogen detection.