Life is able to survive and even thrive under some pretty extreme conditions. Evolution is the ultimate problem-solver, slow but steady, providing clever solutions that allow life to fulfil its basic requirements in an ever-changing environment.

Taking lessons from Nature, a team from Zhejiang University, China, has borrowed a trick from polar bears to create a thermally insulating textile that is wearable and breathable, and which can be readily adapted from passive insulator to active heater, as desired.

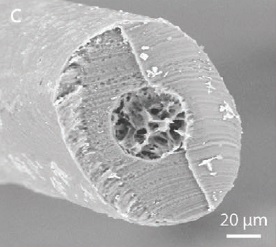

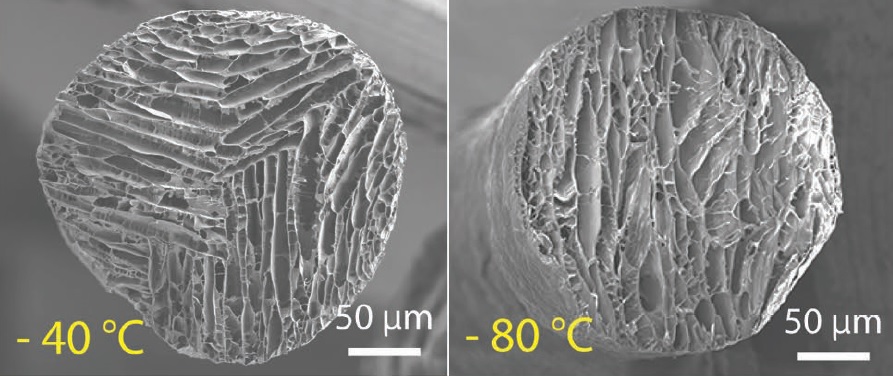

Polar bear hairs are microstructured fibers of roughly 200 µm diameter, with an insulating hollow (porous) core and an aligned shell providing the necessary mechanical stability. To reproduce this combination synthetically has proven tricky, but these researchers have hit upon a method that allows them to fabricate such fibers continuously and on a large scale.

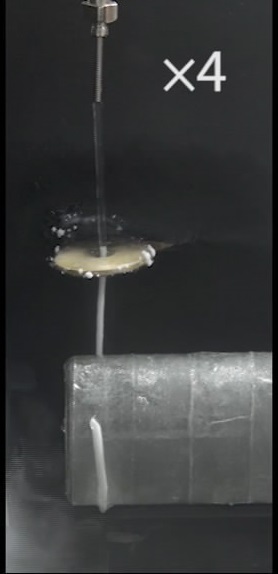

Freeze spinning gives fibers the same microstructure as polar bear hairs (image taken from the movie in the supporting information of this paper).

Their method, called ‘freeze spinning’, brings together two techniques: directional freezing and solution spinning. It involves the extrusion of an aqueous starter solution to create a liquid wire, which is passed slowly through a cold copper ring to generate directional ice crystal growth. This frozen fiber, with its aligned porous microstructure, is preserved by freeze drying and then used to weave insulating textiles.

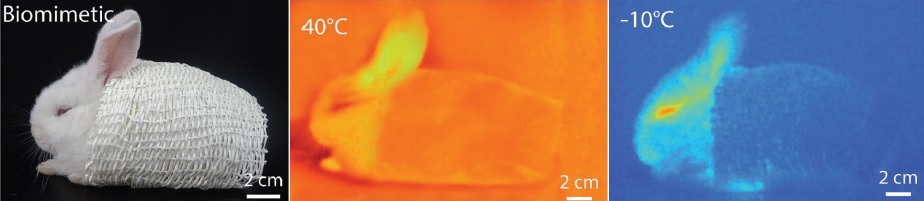

Silk was chosen as a base material to demonstrate the technique for stealth applications. A rabbit wearing the biomimetic silk-based textile was invisible to an infra-red camera at all tested background temperatures (-10 to 40 degrees).

In a separate experiment, carbon nanotubes (CNTs) were added to the fibers to create an electrically conductive network. The textile woven from these fibers was then connected to an external circuit and its temperature was able to be raised by over 10 degrees in less than a minute. Control over the exact temperature change was demonstrated and, the authors say, could be managed by a portable battery. By mixing this conductive textile with CNT-free layers, a hybrid insulating/heating material was generated.

See for yourself why this exciting Advanced Materials Communication is getting so much media attention.

Interested in wearable functional textiles? Take a look at these articles: