Polymer fibers are of tremendous interest because of their unique physicochemical properties, such as large specific surface area, multiple surface functionalities, and superior mechanical properties

Polymer fibers are of tremendous interest because of their unique physicochemical properties, such as large specific surface area, multiple surface functionalities, and superior mechanical properties. These properties make them widely applicable in various areas such as membrane fabrication, tissue engineering, biomedical devices, or optical sensors. Among the methods to fabricate fibers, high-voltage electrospinning is a valued technique for preparing fibers at the nanoscale due to its low-cost set-up, simple operation, high yield, and morphology-controllable characteristics.

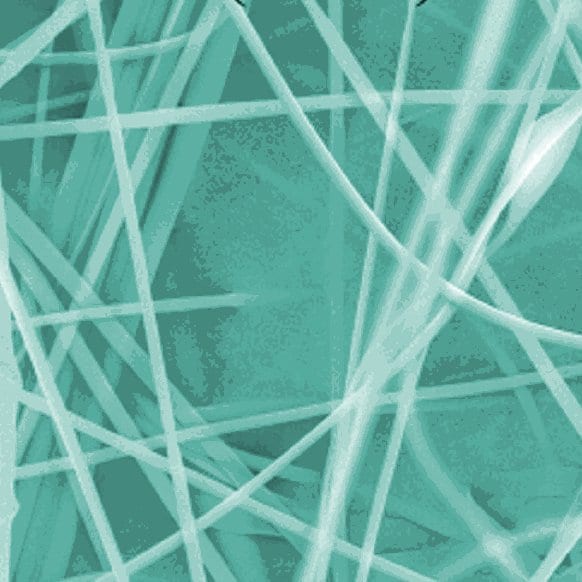

In their present paper, Zhanhu Guo et al. (Lamar University, USA) report the optimum condition to electrospin bead-free and uniform poly(vinyl alcohol) (PVA) nanofibers by adjusting the electric voltage, polymer concentration, volume feed rate, and working distance. The authors have also discovered that inexpensive sodium chloride and iron nitrate, after dissolving in PVA aqueous solution, have a significant effect on the quality of the nanofibers.

An appropriate amount of salt facilitates the formation of slim and uniform nanofibers and eliminates the bead defects effectively. However, polymer solutions with more salts, such as 1.0 wt.-% iron nitrate, provide non-uniform and beaded fibers. Iron nitrate in the PVA fibers changes the ratio of C-C and CH2 groups in the PVA matrix and has a strong interaction with PVA through the ions. The solution viscosities of the pristine PVA, PVA/NaCl and PVA/iron nitrate increase slightly with the addition of small amount of salts.

It is shown that the ionic strength rather than the viscosity is responsible for controlling the quality of electrospun nanofibers. The fabricated fibers are expected to have great potential for use in industrial areas such as sensoring and environmental remediation.