Several decades of development of material processing techniques that involve severe plastic deformation (SPD) have brought about a plethora of remarkable results. Arguably the most impressive one is the formation of nanostructures within the bulk of the deformed solid. A tangible practical outcome of SPD processing is the creation of materials with outstanding physical and mechanical characteristics stemming from their extremely fine inner structure (average grain size of the order of 100 nm).

Several decades of development of material processing techniques that involve severe plastic deformation (SPD) have brought about a plethora of remarkable results. Arguably the most impressive one is the formation of nanostructures within the bulk of the deformed solid. A tangible practical outcome of SPD processing is the creation of materials with outstanding physical and mechanical characteristics stemming from their extremely fine inner structure (average grain size of the order of 100 nm).

In this article Y. Beygelzimer, Y. Estrin and R. Kulagin present a new realm of applications of SPD processes, which they believe is no less exciting than the established ones. The authors say “we are talking about the possibility to employ SPD techniques for creating smart inner architectures of solids by embedding in them engineered structures from various materials. We refer to this approach as SPD-induced synthesis”.

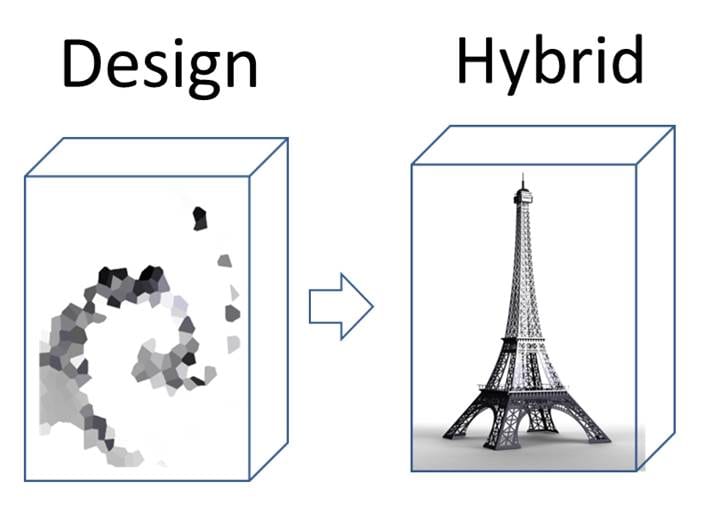

SPD-induced synthesis is a potent new approach that extends the concept of composite materials. Such composites as armoured concrete, plywood, fiberglass, bi-metals, etc. are quite familiar to the experts and the general public alike. The quest for novel materials that possess new characteristics not achievable to date with conventional composites has drawn the attention of researchers to the materials Nature uses in living matter. High-performing natural composites are also comprised of dissimilar materials. What distinguishes them from the man-made composites is a greater variety of geometries and arrangements of the constituents. A look at the structure of bone and muscle tissue, or at the make-up of wood and shells suffices to demonstrate that. It is the geometrical shape and mutual arrangement of the components, alongside their composition and microstructure, what determines the outstanding characteristics of natural composites. Artificial composites that build on the potentialities of the shape as an essential design parameter are referred to as hybrid materials. Of course, one would not necessarily wish to have a hybrid with reinforcement in the shape of the Eiffel Tower, as seen in the above figure, but the principle of process design leading to intricate inner architectures is well-captured by this illustration.

The article discusses the possibilities of creating hybrid materials with promising architecture, while simultaneously producing a desirable submicron scale structure, which are offered by SPD processing techniques. Specific solutions for design of hybrid materials, particularly by embedding thin soft layers in a low-ductility UFG matrix (‘artificial crystals’), considered in the paper, were shown to be attractive as a way to enhance the resistance to strain localizations and the tolerance to overloads – without sacrificing strength.