Small and multifunctional electronics modules integrating passive components including electricity generation and storage are needed in next-generation personal terminals like smartphones. A passive component may consist of various ceramics such as BaTiO3, Al2O3, and ZnO, and metal for wiring. Because ceramics are typically fired at temperatures greater than 1000°C, it is difficult to incorporate high-temperature ceramics with low-resistivity, low-melting-point metals such as Cu with a melting point of 1083°C.

Small and multifunctional electronics modules integrating passive components including electricity generation and storage are needed in next-generation personal terminals like smartphones. A passive component may consist of various ceramics such as BaTiO3, Al2O3, and ZnO, and metal for wiring. Because ceramics are typically fired at temperatures greater than 1000°C, it is difficult to incorporate high-temperature ceramics with low-resistivity, low-melting-point metals such as Cu with a melting point of 1083°C.

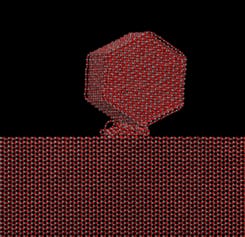

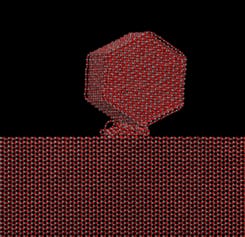

Now, researchers at Fujitsu Laboratories Ltd. in Japan have found that a dense, thick, and organic-binder-free ceramic film consisting of stress-free nanoparticles could be obtained at room temperature by making use of the unstable and high-surface energy amorphous phase on the surface of particles that are produced in the deposition process for bonding the particles.

Photolithography and wet etching for patterning and processing can be adapted to the thick ceramic green-state film. The sintering of the film takes place at temperatures lower by 500°C compared with bulk ceramics, while having the same electrical properties as bulk ceramics. They demonstrate that a multilayered structure consisting of various ceramics with different sintering temperatures and Cu wiring can form on a Cu foil below 1000°C. Their methodology could be expanded to energy storage devices and flexible electronics applications.