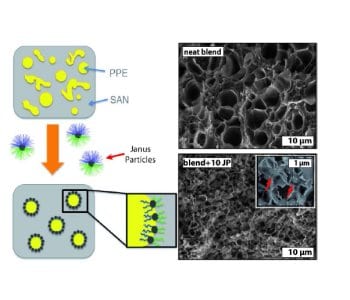

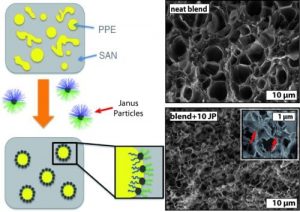

Nowadays, it is virtually impossible to let a day go by without encountering polymer foams. They are present everywhere, from everyday packaging materials and isolations in buildings to complex shapes of cushions in cars. Most of the commercial polymer foams up to now are made of one single polymer, and only few polymer blend foams have so far reached the market. Intensive research is being invested toward foaming these complex materials as extra measures, especially in case of immiscible polymer blends, needs to be taken. In immiscible blends, there is a need for a tailor-made third component known as compatibilizer that bonds the phases together and ensures good mechanical properties. On the other hand, during foaming, usually nucleating agents are used to homogenize the cellular structure and produce fine nanocellular polymer foams. In this study, highly efficient Janus particles were employed that fulfill both tasks, i.e., acting simultaneously as compatibilizers and foam nucleating agents.

Nowadays, it is virtually impossible to let a day go by without encountering polymer foams. They are present everywhere, from everyday packaging materials and isolations in buildings to complex shapes of cushions in cars. Most of the commercial polymer foams up to now are made of one single polymer, and only few polymer blend foams have so far reached the market. Intensive research is being invested toward foaming these complex materials as extra measures, especially in case of immiscible polymer blends, needs to be taken. In immiscible blends, there is a need for a tailor-made third component known as compatibilizer that bonds the phases together and ensures good mechanical properties. On the other hand, during foaming, usually nucleating agents are used to homogenize the cellular structure and produce fine nanocellular polymer foams. In this study, highly efficient Janus particles were employed that fulfill both tasks, i.e., acting simultaneously as compatibilizers and foam nucleating agents.

Volker Altstädt et al. from Bayreuth University combined their expertise in chemistry and polymer engineering to develop foams with nano structured lamella and struts with remarkable properties from immiscible polymer blends compatibilized with Janus particles in an industrial scale. Janus particles are three dimensional, two-faced particles with each side having a different chemical structure. In the present work, the employed Janus particles had different coronas that are miscible with one of the blend phases. In immiscible poly(2,6-dimethyl-1,4- phenylene ether) / poly(styrene-co-acrylonitrile) (PPE/SAN) blends, the presence of Janus particles produces not only much finer morphologies in the compact blend materials after compatibilization, but shows even more significant effects on the foam morphologies due to larger surface area available for nucleation, which result in a very fine cellular structure. Through temperature induced batch foaming with CO2 as blowing agent, foams with densities of around 500 kg/m3 and average cell size below 1 μm are obtained. The strong, Janus particle mediated bonding at the interface can also promote the formation of open-cellular structures in the polymer foams.