Illustration by Kieran O’Brien

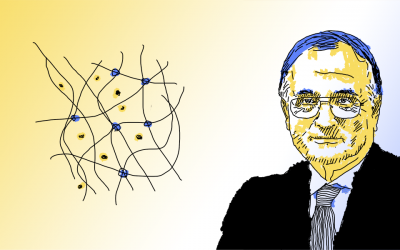

For over five decades, Harvard professor George Whitesides has dedicated his life and career to the pursuit of knowledge, making considerable contributions to research in chemistry and connecting its applications with fields as diverse as engineering, robotics, and healthcare.

Having described himself as “curious by nature”, he endeavors to apply his research to society’s greatest challenges, breaking through a number of frontiers in the process. “I have become interested in how best to make university research both intellectually interesting (that is, science for the sake of understanding) and practically useful (that is, technology that works),” he once wrote.

For Whitesides, applying research to meet societal needs has become of the utmost importance, where “researchers must always be able to answer the question: ‘who cares?’”. In honor of his 82nd birthday this August, this edition of Pioneers in science aims to highlight the life and influential career of chemist George Whitesides.

Early life and education

Whitesides was born on August 3, 1939, in Louisville, Kentucky, USA. As the son of a chemical engineer, he was exposed to science from a young age and began working as a lab technician at his father’s company in his teens, where he cleaned glassware and did analyses of materials. Whitesides has described this mundane task of cleaning glassware as “soothing”, highlighting the importance of enjoying the small, day-to-day tasks inherent in one’s career.

After considering both math and English as university majors, he was encouraged to focus on chemistry, which he studied as an undergraduate at Harvard. “Since I was at least an experienced technician, I did well enough, and chose to stay in chemistry,” said Whitesides in an interview.

After leaving Harvard in 1960, he received a Ph.D. from the California Institute of Technology (Caltech) under John Roberts, where he was trained as a hard-core physical organic chemist. “Chemistry at graduate school was a logical progression, and from there I went to work in a university, because it seemed more appealing to work on whatever I wanted to work on, rather than doing what somebody else wanted me to do,” he said.

He went from Caltech to an assistant professor position at the Massachusetts Institute of Technology (MIT) and, after 19 years, joined Harvard University in 1982, where he is now the Woodford L. and Ann A. Flowers University Professor.

Birth of soft lithography

“Chemistry is no longer just about atoms and molecules, but about what it, as a field with unique capabilities in manipulating molecules and matter, can do to understand, manipulate, and control complex systems composed (in part) of atoms and molecules,” he wrote in an essay published in Angewandte Chemie in 2015

In keeping with this perspective on the chemical sciences, he has argued that chemistry as a field has a tendency to focus on narrow aspects of big problems and train “molecular technicians”. However, chemistry does not have to be pigeon-holed like this; it is in fact the best-equipped discipline to work on the most engaging problems in fundamental and applied science.

A perfect example of this philosophy in practice is his role in the development of soft lithography. Soft lithography is a suite of nanofabrication techniques that use “soft” organic materials to make microscale and nanoscale structures for applications ranging from healthcare to robotics.

In 1965, Gorden Moore, founder of both Intel and Fairchild Semiconductor, projected that the number of transistors on a microchip would double roughly every two years, resulting in faster and more capable computers — a prediction named Moore’s Law. But this also meant that these advances in computer science would eventually reach a limit, as the ability to fit smaller and smaller devices onto chips would also reach its limit as a result of our ability to mass produce micro- and nanoscale structures.

For Whitesides, this became an interesting problem. A nanofabrication technique that was easy-to-use and could thus be widely disseminated was the key to solving it. In the 1970s, the Whitesides group was studying surface chemistry and the characterization and application of the self-assembling monolayers of organic molecules. In self-assembly, molecules or objects arrange themselves in a stable fashion to form well-defined patterns. This ability flowed naturally into the development of soft lithography, where self-assembled monolayers of organic molecules are used as templates to fabricate patterns on a surface.

In little more than two decades, soft lithography became a standard production technique in many areas of engineering and materials science. Nanofabrication techniques based on soft lithography provide a convenient, low-cost, and effective method for manufacturing micro- and nanostructures. The game changer is its ability to function under ambient conditions, and not require a stringently controlled environment (e.g., a cleanroom).

One intriguing field that has stemmed from his soft lithography work is microfluidics or “lab-on-a-chip” technologies, which can overcome barriers to create easy-to-use, portable, inexpensive, disposable, fast, and scalable diagnostics for developing nations. The diagnostic tests designed by Whitesides’s laboratory fit on a postage stamp, cost less than a penny, and can accurately detect diseases ranging from liver injury to sickle cell disease.

Projects like these represent what Whitesides calls intellectual merit, that is, technology that is driven by asking fundamental questions. It involves designing devices that are as simple as possible and that provide an economical, robust, and functional benefit.

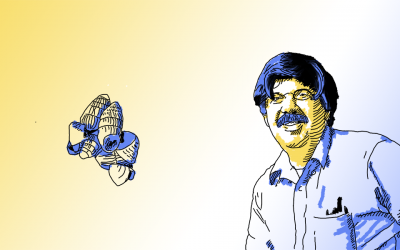

Soft lithography has also found application in engineering and robotics and helped pioneer the field of soft robotics, where its versatility has allowed scientists to fabricate customizable structures made from soft polymer-based materials to build “soft robots” capable of more sophisticated and fluid motion.

“Imagine a robot with arms that are soft, flexible — and yet strong. Such a robot would be able to solve many of the challenges associated with caring for the growing numbers of elderly and sick. As time goes on, this has become an issue of personal interest to me,” said Whitesides in an interview with the Technical University of Denmark in 2016.

Compared with complex and relatively expensive hard robots, soft robots have an enhanced ability to move delicate objects, are more adaptable when it comes to complex, unfamiliar environments, and are lightweight. Thanks to these pioneering developments, the field of soft robotics is now more closely involved with materials science and has opened up the field for more collaborative development.

Interdisciplinary science at its best

Whitesides is undoubtedly one of the most imaginative scientists and inventors active today, tackling challenging problems to provide solutions to meet the needs of society. His call for the field of chemistry to refocus on real world problem solving is one that has massive resonance today.

His work has, of course, extended far beyond the tiny snippet described here. His research group today works on problems as diverse as the origin of life and the control of fires. But the one common element binding this work together is that the answer to the question “Who cares?” is never hard to find.

Read more Pioneers in Science stories here.