Fiber grating inscription by ultrashort laser pulses has many advantages in comparison to continuous wave and long pulse lasers. Especially, it allows inscription in nonphotosensitive fiber materials. Its enormous flexibility opens up a wealth of new grating designs.

Optical fibers are much more than mere ”light pipes”. As already demonstrated at the beginning of the sixties, a fiber terminated with partially reflecting ends acts as an analog of a Fabry-Perot interferometer resonant cavity. Today, world-spanning optical fiber networks rely on low-loss fibers and on amplification in erbium-doped active fibers.

Optical fibers are much more than mere ”light pipes”. As already demonstrated at the beginning of the sixties, a fiber terminated with partially reflecting ends acts as an analog of a Fabry-Perot interferometer resonant cavity. Today, world-spanning optical fiber networks rely on low-loss fibers and on amplification in erbium-doped active fibers.

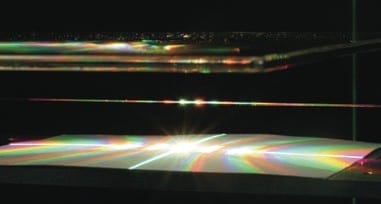

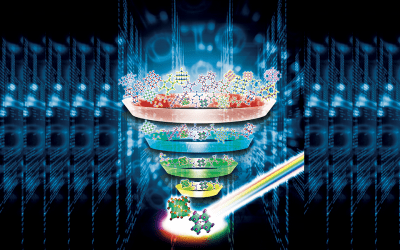

Fiber lasers themselves are now able to deliver powers in the kW regime and are commercially used e. g. for material processing. The backbones of fiber technology are in-fiber components used for filtering, reflection and mode conversion. The most prominent one is the fiber Bragg grating (FBG). Their production became practicable by inscribing the FBG via side illumination by a UV-laser. The response of a FBG can be shaped spectrally by spatially varying the period (chirp) and the refractive index profile (apodization). Tilted FBGs allow access to the cladding-guided modes of a fiber, enabling sophisticated microdisplacement sensors.

The bottleneck of employing fiber technology for fiber lasers has been that efficient grating inscription requires photosensitivity, e.g. by germanium and boron codoping or hydrogen loading. However, such techniques are restricted to the fiber core and require a precise chemical finetuning in order to keep the guiding properties of the fiber intact. Grating formation in pristine fibers needs very long exposure times. Fibers employed in today’s high power lasers are a challenge to common inscription techniques: large core diameters, high rare-earth dopant concentration and air cladding or photonic crystal geometries represent the most important obstacles for commercial FBG production.

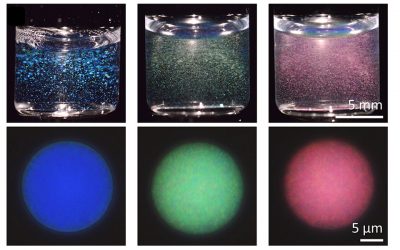

The use of ultrashort laser pulses is an attractive alternative for these sophisticated applications. The most important advantage is that it allows inscription in nonphotosensitive fiber materials. A femtosecond (fs) pulse written FBG also has a unique coupling behavior, due to a refractive index change that is independent from the fiber geometry. Over the last years ultrashort pulse laser micromachining has emerged as a new key technology for integrated fiber optics. In a review article, Jens Thomas and his colleagues from the University of Jena and the Fraunhofer Institute for Applied Optics and Precision Engineering in Jena, Germany give an overview of the principal inscription techniques and the physical properties of fs pulse written in-fiber gratings. Selected applications of such gratings for sensing and fiber lasers are discussed.

Since the grating crosssection is no longer determined by the dopant concentration, more elaborate fiber grating designs are possible such as grating structures within the cladding or highly localized intracore modifications, which enable new grating designs that tap the huge potential of higher-order fiber modes. Specially polarized feedback can be obtained, e. g. a fully radially polarized beam. All these solutions are especially attractive for a cheap and robust integration in fiber lasers.