Imagine that you received a new painting or a poster of your favorite band. One way to put it up is using double-sided tape — a fast and simple solution that does not damage the wall. However, sometimes that the adhesion, or the bonding of one surface to another, is not strong enough, and the object might fall.

To make stickier tape, researchers from the École Polytechnique Fédérale de Lausanne, Switzerland, North Carolina State University, and the University of Electro-Communications in Tokyo proposed a simple method that relies on surface treatment of the tape with a CO2 laser cutter found in almost every workshop, making this method easily accessible to industry and academia, or even for everyday use.

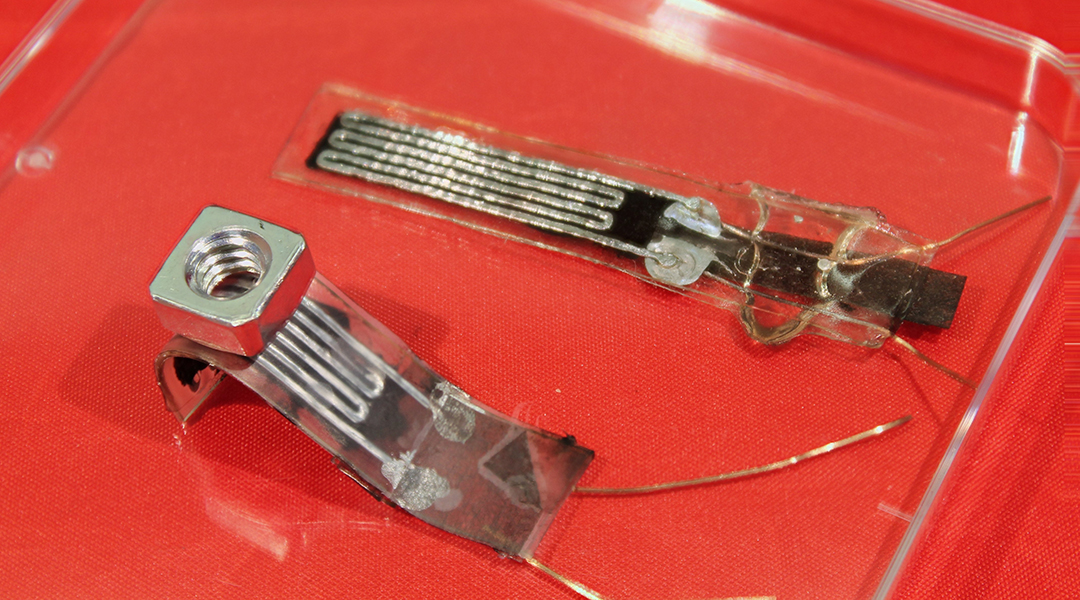

This study uses a popular double-sided sticky acrylic tape known as “very high bond”, which is used in different industries because of its high durability, flexibility, strong bonding, resilience, and ability to stick to a large range of materials. Moreover, it has proven itself in rapidly developing areas like soft and wearable robotics, contributing as a connecting layer or a material for soft-matter devices, such as soft sensors and actuators.

Surface treatments can be used tune the adhesion of the very high bond tape for these specific applications, leading to a longer lifetime for the soft-matter devices. Adhesion tuning can be practical for soft devices mounted on external substrates, such as skin mountable sensors. Similarly, treated and therefore stickier tape could enhance the grasping force of soft grippers by increasing the tackiness of the outer surface of the device.

The tape used in the study is made up in part of acrylic polymers — large molecules made up of long chains or networks of smaller molecules called monomers. The polymer network is a combination of two polymers, both of which are chemically or physically crosslinked.

To enhance the adhesion, researchers put the piece of the very high bond tape in the laser cutter, which then etches the upper surface, making it stickier and more liquid. After mechanical and chemical analysis of the surface, the researchers concluded that adhesion changes are due to the slicing of the polymer network by the laser. The resulting shortened polymer chains change the viscosity and elasticity of the tape’s surface.

The researchers identified systematic guidelines on how surface treatment under different applied laser doses influences the forces between the very high bond tape and different substrates. Now, any user can put in the required parameters, perform the surface treatment, and enjoy better adhesion.

The method can selectively facilitate an increase or a reduction in adhesion. The very high bond tape surface can be destroyed due to the wrinkles formation by applying a very high dose. Therefore, it would enable easy disassembling of soft devices, such as wearable sensor that track heart rate or novel soft watches on your hand. Nowadays, these devices are usually made irreversibly, but allowing for recycling might provide a more sustainable fabrication route for polymer-based soft devices.

This novel approach to recycling could help to reduce the use of new non-biodegradable polymers for example acrylics or thermoplastics. Thus, this way of plastic waste reduction, can prevent new leakages of waste into the ecosystem and decrease their environmental footprint.

Reference: Yegor Piskarev, et al., Enhancement of Pressure-Sensitive Adhesive by CO2 Laser Treatment, Advanced Engineering Materials (2022). DOI: 10.1002/adem.202200355

Disclaimer: The author of this article participated in the study