Periodic three-dimensional (3D) structures with nanoscale constituents, often referred to as ‘‘nanolattices’’, are of extensive interest recently due to the rapid advances in additive manufacturing (such as 3D printing) at the micro/nano-scale. They have great potentials to be used for a variety of engineering applications, such as light-weight structural materials, functional frameworks for sustainable energy, scaffolds for cells culturing and drug delivery, etc.

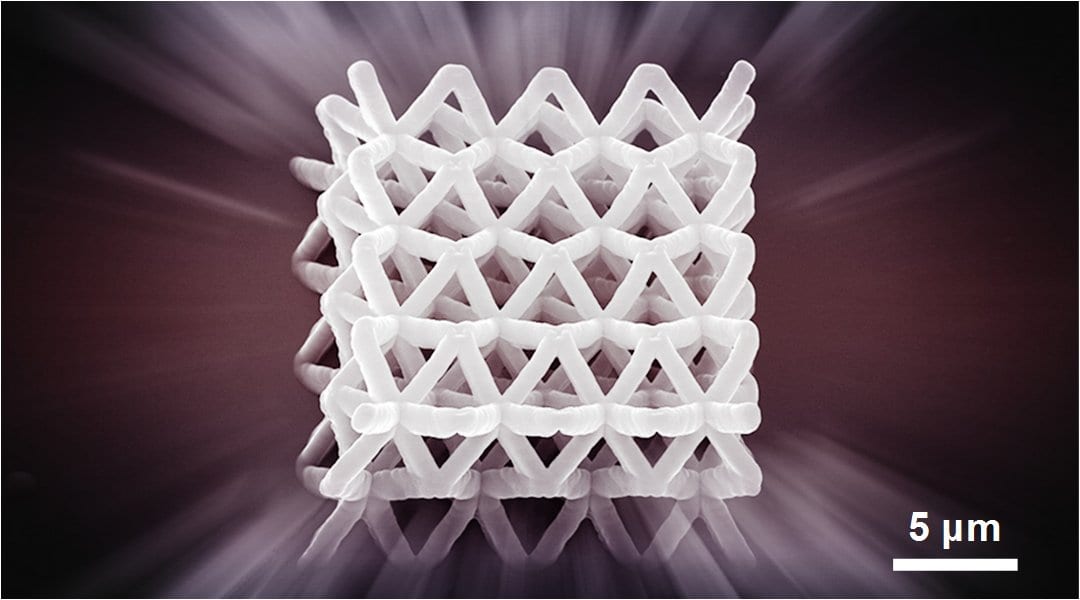

High-entropy alloy (HEA), on the other hand, is a new kind of alloy constructed with equal or nearly equal quantities of five or more metals, showing unprecedented properties owing to their unique alloy design concept, tunable composition/microstructure, and adjustable mechanical properties as compared to conventional metal/alloys. By altering the design and material composition of these micro/nanolattices, it is possible to produce a wide variety of materials with unprecedented properties that defies traditional mechanics, such as strong yet ultra-lightweight structures. Thus, to harness “the smaller, the stronger” behavior emergent at nanoscale and to proliferate HEA characteristics onto materials with macroscale dimensions, in work by Yang Lu et al. from City University of Hong Kong, microfabricated three-dimensional polymeric nanolattices were conformably coated with a thin layer of high-entropy alloy (CoCrFeNiAl0.3) film via physical vapor deposition.

The resulting structures demonstrate structural uniformity and desirable mechanical strength upon various characterizations, including in situ SEM compression testing and 3D atomic-probe tomography (APT). Additionally, inspired by composite designing principles, the polymer/metal core-shell structures clearly exhibit enhanced mechanical properties in comparison to their pristine constituents. This is the first time to combine high-entropy alloy with nanolattice structures manufactured by 3D laser lithography, which opens a new route to design and fabricate architected lattice metamaterials with tunable mechanical properties.