Sticker-type electronics give electronic functions to unconventional substrates such as a paper or human skin – in fact, potentially any diverse curvilinear substrate. To enable such stick-and-play systems, it is necessary to fabricate thin, stable membrane-type ultrathin devices and manipulate them into printable formats.

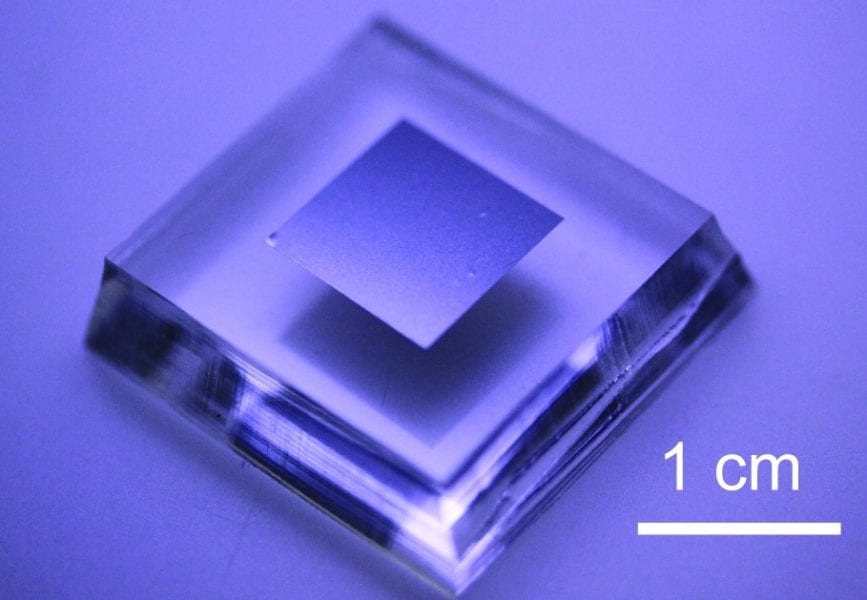

Now, new research by By Suk Ho Kim, Jongwon Yoon and co-workers at the Gwangju Institute of Science and Technology in Korea demonstrates an advanced methodology to guarantee both stability in device fabrication and high-efficiency transfer printing of the final devices. Contrasting with current methods, which use a planar handling substrate, they employ a water-soluble sacrificial polymer layer on a dimpled handling substrate that enables the topological confinement of the sacrificial residue inside and near the dimple structures during the etching and drying processes of the sacrificial layer to tether the ultrathin substrate gently. This technology provides a high yield of transfer printing in a deterministic manner without altering the position of printable designs to formulate, for example, sticker-type ZnO TFTs.