New research has demonstrated a novel high speed roll-to-roll process for nano- and microstructuring of large areas of plastic foils. Replication of nanostructures with size below 100 nm was shown at line-speed of 60 meters per minute. The process has potential to accelerate the integration of nanostructured materials in a broad range of applications, including optical, technical and functional surfaces and devices. Possible applications may even include cast molding of advanced materials for photo-voltaic, thermo-electric, electro-active and electro-storage applications, where nanostructuring often leads to improved properties. The process is known as roll-to-roll extrusion coating (in the packaging industry commonly referred to as co-extrusion), and is widely used for production of smooth polymer films, but has not previously been employed for replication of nanostructures.

New research has demonstrated a novel high speed roll-to-roll process for nano- and microstructuring of large areas of plastic foils. Replication of nanostructures with size below 100 nm was shown at line-speed of 60 meters per minute. The process has potential to accelerate the integration of nanostructured materials in a broad range of applications, including optical, technical and functional surfaces and devices. Possible applications may even include cast molding of advanced materials for photo-voltaic, thermo-electric, electro-active and electro-storage applications, where nanostructuring often leads to improved properties. The process is known as roll-to-roll extrusion coating (in the packaging industry commonly referred to as co-extrusion), and is widely used for production of smooth polymer films, but has not previously been employed for replication of nanostructures.

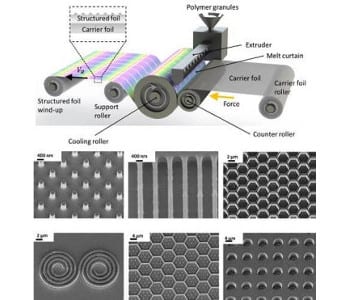

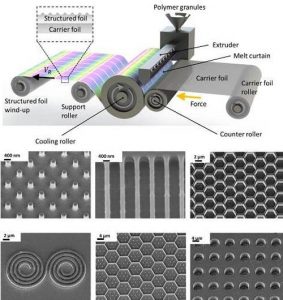

Among benefits of the process are availability of a wide range of commercial extruders, off-the-shelf extrusion grade polymers, functional additives, polymeric materials with good diffusion barrier properties, and the overall maturity of the technology. In roll-to-roll extrusion coating a molten polymer film is extruded through a flat nozzle forming a melt curtain, then stretched in air, and finally laminated onto a carrier foil. The lamination process takes place as the melt curtain is squeezed between a cooling roller and a rubber counter roller. By attaching a nanostructured metal sheet to the surface of the cooling roller, the relief structure from the sheet can be replicated onto a plastic foil.

In this article by Rafael Taboryski et al. it is demonstrated that nanostructures with typical linewidths in the range 100 – 400 nm are best replicated using semi-crystalline polymers such as polypropylene (PP), running at high roller line-speed of 60 meters per minute, and high cooling roller temperature of 70° C. Replication in other common polymers like polyethylene (PE) and polystyrene (PS) was not possible for nanostructures. However, structures with linewidths and depths above ca. 400 nm were more forgiving and allowed for a wider range of materials. For such microstructures, it was found that process parameters had to be individually optimized for each pattern, indicating that viscoelastic flow into the relief plays a more important role.