A team of researchers at Stanford University, USA, has developed shape-controlled, self-wrapping 3D electronics based on carbon nanotubes. For the first time, a shape memory polymer is used in electronic devices, with performance demonstrated in the form of transistors, gas and temperature sensors, and memory devices.

Recent advances in ultrathin devices have facilitated the development of new technologies, from flexible displays to myriad medical applications. While electronics are conventionally designed for two-dimensional surfaces, all of the living and inanimate systems encountered in our daily lives are three-dimensional. For a full integration of developing thin-film technologies, electronics that can be controllably shaped to irregular contours are highly desirable.

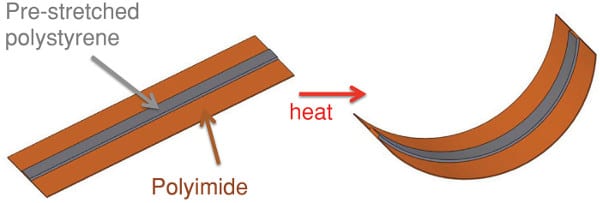

Using a bilayer structure of shape memory polymers and polyimide, shape-controlled, self-wrapping 3D single-walled carbon nanotube (SWNT) electronics are developed. Local shape control is achieved with electrically activated pre-patterned heaters, which allow the curvature to be tuned in various directions at different times. The researchers present this local control by fabricating a foldable “lotus flower”, which folds up on increasing the heating temperature from 110 to 140 °C. Further heating beyond 190 °C caused the “flower” to unfold again, as the polystyrene softened. Finite element method simulations give insight into the internal stress distribution during the folding process.

Finite element method simulations indicate the internal stress distribution during the shape evolution of a lotus-shaped polymer–polyimide structure.

The ability of these flexible electronics to wrap around various everyday objects is also demonstrated, presenting the potential for their practical application as portable sensors. In this study the devices were heated up to 220 °C, with no degradation in performance before or after deformation. While SWNTs were chosen due to their favorable mechanical properties and projected low-cost processing, the authors point out that their shape-controllable bilayer structure can be applied to other flexible electronics systems. Exciting prospects could be on the horizon, as the path has been paved to incorporate bidirectional shape memory polymers to study reversible shape-memory effects for electronics.

Advanced Science is a new journal from the team behind Advanced Materials, Advanced Functional Materials, and Small. The journal is fully Open Access and is free to read now at www.advancedscience.com.