Polymer-based carbon nanotubes exhibit excellent mechanical, electrical and thermal properties, giving them great potential as high-performance materials. Marilyn Minus and co-workers (Northeastern University, USA) applied shear-flow spinning to produce poly(vinyl alcohol) (PVA) / single-wall carbon nanotubes (SWNT) composite fibers with high nanotube loadings and a unique combination of high-performance properties.

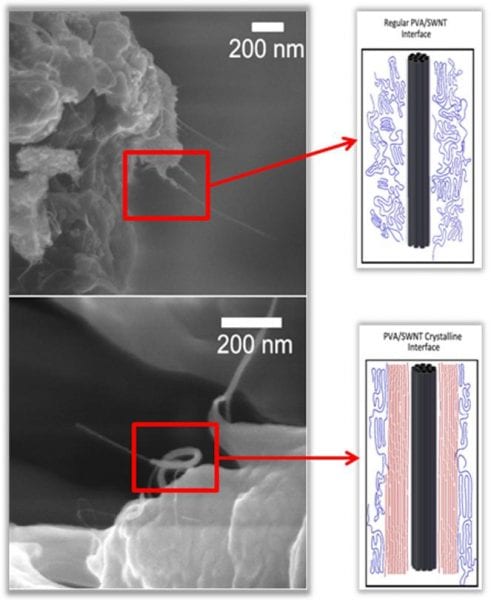

The resultant fibers demonstrated excellent mechanical properties, which surpassed some commercially available high-performance fibers like Spectra, Kevlar, Dyneema, and high-strength carbon fibers. The excellent mechanical performance of the composite fibers is mainly due to the changes in the PVA structure in the presence of the nanotubes. These structural changes include better polymer chain alignment and packing, resulting in stronger polymer chain interaction. When composite fibers are stretched, these structural changes in the polymer increase load transfer to the nanotubes which improves the composite fiber performance.

The resultant fibers demonstrated excellent mechanical properties, which surpassed some commercially available high-performance fibers like Spectra, Kevlar, Dyneema, and high-strength carbon fibers. The excellent mechanical performance of the composite fibers is mainly due to the changes in the PVA structure in the presence of the nanotubes. These structural changes include better polymer chain alignment and packing, resulting in stronger polymer chain interaction. When composite fibers are stretched, these structural changes in the polymer increase load transfer to the nanotubes which improves the composite fiber performance.

These high-performance composite PVA/SWNT fibers are well-suited for critical applications such as aerospace vehicles, bulletproof vests, and industrial ropes/cables which require lightweight and strong materials.