With coral reefs nearing collapse, cutting-edge materials could be the solution nature desperately needs; if we could engineer materials to restore reefs faster, we may finally be ready to turn the tide for ocean life.

In the last few decades, rapid climate change, ocean acidification, and destructive human activities have pushed coral reefs towards an unprecedented crisis. Quantitively, in recent years, there has been a reduction of ~20% in the number of coral reefs present globally, with projections suggesting a risk of total extinction by 2050 if ocean temperatures rise by only 2 °C. Since a significant percentage of marine species depend on such reefs, this would not only devastate marine biodiversity but also adversely affect our civilization.

While several socio-scientific measures have been taken to rejuvenate and safeguard coral ecosystems, amongst these, coral restoration has emerged as a key response to this challenge. The most widely used method, “coral gardening”—where coral fragments are grown in nurseries and then transplanted into degraded reefs—has proven to be effective, but current attachment techniques using glues, wires, concrete, or ties are slow, unreliable, and may even harm marine ecosystems.

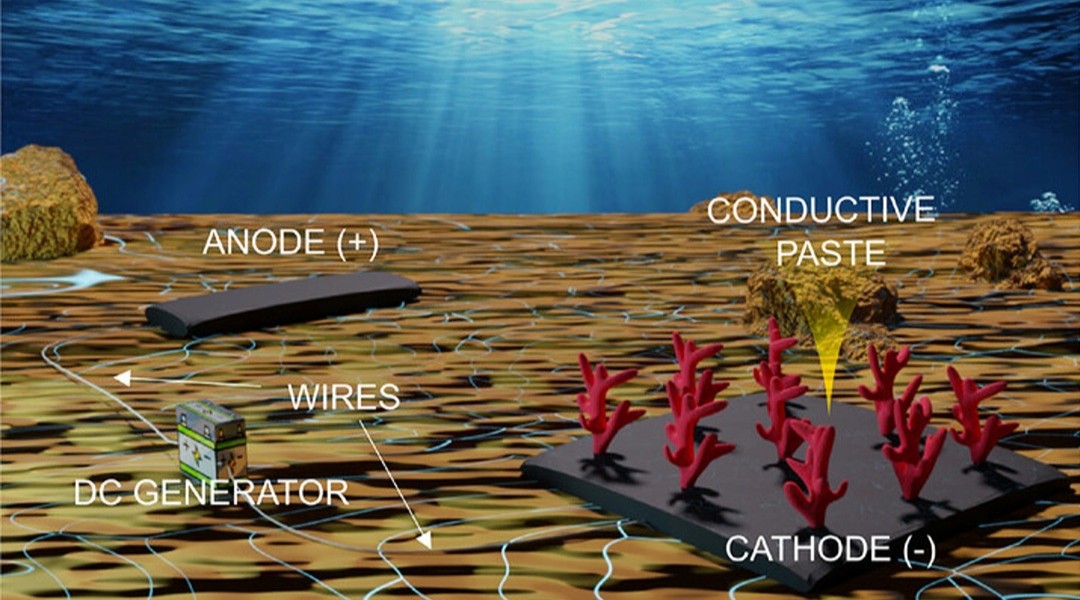

Moreover, accelerating coral growth has remained a major hurdle in this approach due to their inherently slow calcification rates. In contrast, Mineral Accretion Technology (MAT) has emerged as a promising technique which stimulates coral growth using low-voltage electric currents that encourage calcium carbonate deposition. But traditional MAT systems rely on large metal frames and continuous power, which are difficult to maintain and can cause pollution if they corrode.

Researchers collaborating across Italy and the Maldives have now reported the first underwater, eco-friendly, conductive and hardening paste specifically designed for coral restoration. This paste consists of a bio-based and biodegradable acrylate soybean oil matrix and graphene nanoplatelet fillers, and is designed for fast and secure coral attachment while supporting MAT-driven growth, without the need for large metal structures. It combines ease of use with biocompatibility, making it ideal for both aquaria and natural coral reef settings.

“Our approach brings together materials science, marine biology, and electronics to make coral restoration faster, safer, and more scalable,” says Pietro Cataldi, a researcher in Istituto Italiano di Tecnologia (IIT)-Genova and one of the authors of this study. Co-author Simone Montano, a professor at the University of Milano, Italy, and deputy director of Marine Research and High Education Centre in the Maldives, adds, “Innovative technologies like this give us time – time to protect marine ecosystems while waiting for global mitigation efforts to take effect.”

While initial tests have shown promising results, especially in controlled aquarium environments, the team’s next steps involve testing a wider range of coral species, integrating smaller fragments of corals instead of larger ones to boost growth and maturity (microfragmentation technique). Such developments can then be incorporated in realization of renewable energy sources, such as modular solar panels or underwater turbines, to power MATs in remote reef systems.

Reference and Featured Image Credit: G. Corigliano et al., Active Biopaste for Coral Reef Restoration, Advanced Materials (2025). DOI: 10.1002/adma.202502078