Toward ultrastretchable wearable electronic devices and soft robotics, liquid metals such as gallium-based alloys have been actively adopted as conductive and structurally compliant materials in conjunction with soft polymeric substrates and encapsulation. Among various patterning techniques for liquid metals, the direct writing relying on translation stages, a pressure source, and a dispensing needle is the most affordable approach in a general laboratory setting since other patterning techniques require, to some extent, conventional microfabrication in a clean room.

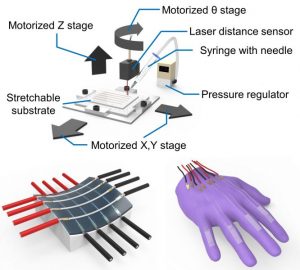

Concept of the 4-DOF liquid metal writing systems (top) and their resulting printed structures (bottom).

While the direct writing of liquid metals has been employed to make strain gauges and tactile sensors and has enabled even 3D structures by stacking liquid metal droplets, demonstrations to date are limited to planar substrates; either flat or inclined.

Four degrees-of-freedom (4-DOF) direct writing on uneven surfaces presents a promising solution to directly print various liquid metal patterns on curved surfaces thus eliminating any additional labor for and uncertainty from mounting liquid metal patterns on a planar substrate onto a curved object.

To pattern liquid metals on curved surfaces, a unique system relying on 4-DOF motion control of the pressurized dispenser and precise sensing of the dispensing tip-substrate distance has been proposed and built by using motorized linear and rotation stages, electronic pressure regulators, and a laser distance sensor.

Prof. Jungchul Lee from Korea Advanced Institute of Science and Technology, South Korea, notes in his recently published work in Advanced Materials Technologies, that “our 4-DOF direct writing system enables [one to] maintain the dispensing tip-substrate distance, a key parameter for reliable liquid metal patterning, thereby opening up a new manufacturing route for next generation liquid metal devices.”

Jungchul’s co-worker, Young Yoon from Seoul National University furthermore states that “Direct writing of liquid metals on curved elastomeric surfaces simply demonstrates a curved keypad and a glove-type wearable device in a seamless manner. We are excited with these results and hope this work will pave the way for the development of new liquid metal devices for tomorrow.”