By Pei Dong and Jun Lou, Rice University

Owing to their outstanding thermal, mechanical, and electrical properties, carbon nanotubes (CNTs) have attracted great attention since their discovery by Sumio lijima in 1991. Lightweight yet strong, CNTs have long been envisioned as ideal reinforcements in composites and have been widely studied. Among many different structures made of CNTs that are promising for composite applications, buckypapers, CNT “papers” or thin sheets made from an aggregate of randomly oriented nanotubes, demonstrate outstanding properties, ease of fabrication, and potential for scale-up production.

Owing to their outstanding thermal, mechanical, and electrical properties, carbon nanotubes (CNTs) have attracted great attention since their discovery by Sumio lijima in 1991. Lightweight yet strong, CNTs have long been envisioned as ideal reinforcements in composites and have been widely studied. Among many different structures made of CNTs that are promising for composite applications, buckypapers, CNT “papers” or thin sheets made from an aggregate of randomly oriented nanotubes, demonstrate outstanding properties, ease of fabrication, and potential for scale-up production.

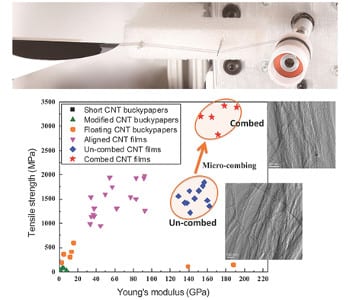

Given their importance, great efforts have been devoted to develop different processing methods, e.g., “Domino pushing”, “Shear pressing” and “Stretching pressing”, for producing high quality buckypapers. Unfortunately, despite the continuous progress made in the past decade, buckypapers still need to be improved in both mechanical and electrical terms to meet their potential. The current generation have a Young’s modulus from 0.08 GPa to 188 GPa, while their tensile strength varies from 0.42 MPa to 2.96 GPa. Their reported electrical conductivity is in the range of 6.53 x 102 S m-1 to 3.5 x 105 S m-1. Researchers in the field are very eager to achieve better properties with simpler methods.

Sometimes, a brilliant discovery can come from a simple idea. Combing, a process to disentangle and further straighten fibers, has been used for centuries in the textile industry to achieve better fiber alignment. Prof. Zhu and his co-workers from North Carolina State University have now applied this traditional method to CNT buckypaper production to make strong and conductive dry CNT films. Two surgical blades were used as the combing tool. The CNT film layer was drawn out from the CNT array, passed through two surgical blades, and finally wound to a rotating mandrel. They noted that the rotating speed cannot be great than 20rpm, otherwise the CNTs are no longer held together by the weak van der Waals force. The best contact angle between the blade and CNT sheet was 80o-85o.

As a simple and effective approach, microcombing successfully improved the CNT alignment and reduced its waviness. The CNT films produced this way demonstrated a Young’s modulus of up to 172 GPa, tensile strength of up to 3.2 GPa, and electrical conductivity of up to 1.8 x 105 S m-1. All these properties are much improved or at least on a par with the previously reported best results for CNT buckypapers. Finally, this novel technique not only requires less rigorous process control, but also fabricates CNT films with improved reproducibility, which could benefit many potential applications in the near future.

Pei Dong is a Postdoctoral Research Associate in the Department of Materials Science and NanoEngineering at Rice University. She is currently working on synthesizing nanomaterial for energy applications and understanding self-stiffening mechanisms in nanocomposites.

Jun Lou is a professor in the Department of Materials Science and NanoEngineering at Rice University. His current research interests include nanomaterial synthesis, nanomechanical characterization and nanodevice fabrication for structural energy, environmental and biomedical applications. More details are available on his homepage: n3l.rice.edu.