Boron carbide is one of the most useful non-oxide ceramics in modern engineering because of its unique combination of low density, high hardness, high melting point, and small thermal expansion coefficient. These characteristics make boron carbide attractive for numerous important applications including lightweight body armors, abrasive wear-resistant materials, and neutron detectors. However, toughening ceramics such as boron carbide has been a long-standing challenge.

Boron carbide is one of the most useful non-oxide ceramics in modern engineering because of its unique combination of low density, high hardness, high melting point, and small thermal expansion coefficient. These characteristics make boron carbide attractive for numerous important applications including lightweight body armors, abrasive wear-resistant materials, and neutron detectors. However, toughening ceramics such as boron carbide has been a long-standing challenge.

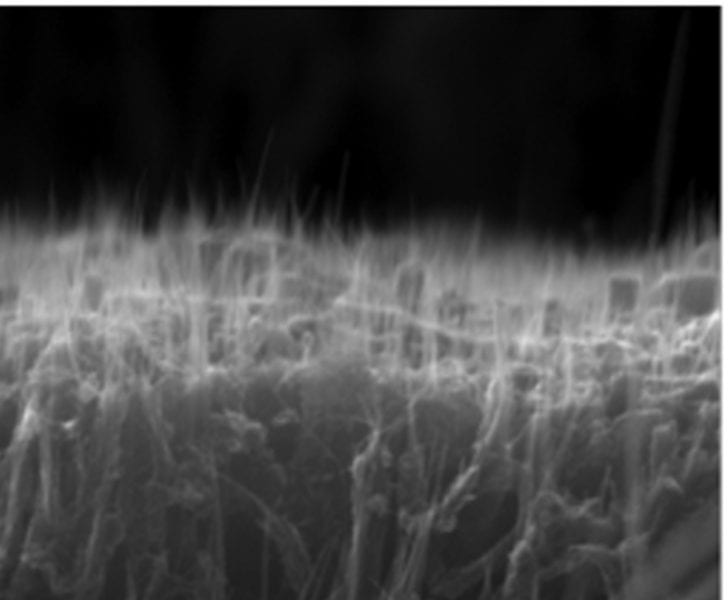

By chemically infiltrating B4C into aligned carbon nanotube (CNT) sheets, a US/China research team has fabricated a high-quality, exceptionally tough CNT/B4C composite. Using the chemical vapor infiltration method, most of the manufacturing problems previously encountered in the fabrication of CNT/B4C composite were overcome. Their CNT/B4C composites simultaneously possess a strongly-bonded tube/matrix interface and an amorphous, crack-free B4C matrix, jointly enabling the composites to have exceptional-high mechanical properties and to withstand oxidization at 900 °C in air. Nanotube pullout is consistently observed in all fractured CNT/B4C samples, showing the remarkable reinforcement of nanotubes to the brittle B4C matrix. Mechanical measurements on individual CNT/B4C nanowires show that the fracture strength of the CNT/B4C nanowires is about 1-2 orders of magnitude higher than that of the bulk B4C, suggesting that the CNT/B4C composites hold a great promise in future applications.