Image credit: DimStock Pixabay

A year into the pandemic, it is now well understood that the transmission of the SARS-CoV-2 virus occurs through airborne droplets or small aerosol particles. As a result, many governments around the world have made social distancing and wearing masks in public places mandatory.

While their is ample evidence to support that these actions are effective in halting the spread of COVID-19, mask wearing is creating a secondary problem: an enormous amount of plastic pollution, which is already one of the biggest environmental issues facing our society.

“We believe biodegradable masks are the answer to this problem,” said Sung Yeon Hwang, professor from the Research Center for Bio‐Based Chemistry at the Korea Research Institute of Chemical Technology (KRICT). “Contaminated plastic masks are difficult to recycle and must be incinerated or sent to a landfill.”

Medical-grade masks are conventionally made using polypropylene plastics, but Hwang and his co-workers — Professor Dongyeop Oh and Professor Jeyoung Park — propose alternative materials with enhanced properties to make biodegradable filters to curb plastic waste.

In a study recent published in Advanced Science, the researchers report a biodegradable and moisture‐resistant mask filter made from polybutylene succinate (PBS) — a biodegradable plastic resin — coated with chitosan nanowhiskers.

The filter material is what the team classifies as a “nonwoven” fabric, which is as sheet or web of structures bonded together by entangling fibers or filaments. “Most filters are basically made of nonwoven fabrics because they contain small pores between the fibers where airborne particles can get trapped, ” said Oh.

To make the filters, Oh explained that a solution containing dissolved PBS is slowly passed through a syringe needle whose tip is under the influence of an applied electric field. “The cotton candy-like, ultra-fine fibers, which are several micrometers in diameter, fall from the tip of the syringe to the floor by the force of the electric field,” added Oh. “Over time, the accumulated fibers create a film, which is the nonwoven fabric,” he said.

This preliminary filter, which on its own would have inadequate performance against small particles, such as SARS-CoV-2 aerosols, is then enhanced with a coating of chitosan nanowhiskers — positively charged microfibers made from the shells of crustaceans. By soaking the filters in a solution of the nanowhiskers, the biodegradable filters become permanently coated and have an increased ability to trap tiny particles as a result of the nanowhisker’s positive charge.

“Current polypropylene filters are charged with static electricity to improve filter performance,” said Hwang. “The drawback, however, is that it loses its static charge in a moist environment [i.e., when wearers breath], and so the filters cannot be reused. Chitosan nanowhiskers, on the other hand, are permanently positively charged and thus adsorb fine particles even in humid conditions. This means that our mask filter is reusable [once disinfected].”

“Infection prevention is proportional to the performance of the mask filter,” added Park. “Cloth masks are poor when it comes to blocking droplets, and high-performance masks such as N95 are gradually weakened by moisture. Our re-usable mask filter retains its performance even after immersion in water and maintains high performance for a long time.”

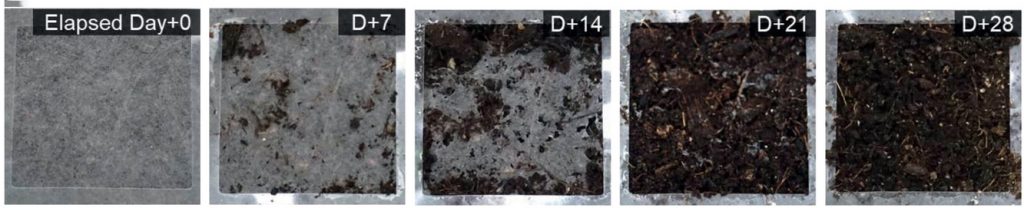

The team’s experiments showed that the biodegradable filter was just as efficient as N95 filters, removing 98.3% of 2.5 µm (PM2.5) particles in a test, and decomposed within 4 weeks in composting soil.

The researchers manufactured their biodegradable filters through a process called electrospinning, which is an already well-established technique used in industry, which they hope will facilitate their commercial availability.

“Any filter manufacturers can buy biodegradable plastics, such as PBS, and make nonwoven filters,” added Hwang. “We think this technology will be easy to implement on an industrial scale and will be very impactful.”

Reference: Sejin Choi, et al., Biodegradable, Efficient, and Breathable Multi‐Use Face Mask Filter, Advanced Science (2021). DOI: 10.1002/advs.202003155