In our tech-savvy world, the demand for wearable electronic devices is increasing. Wearable devices have many applications, including portable power generation, advanced physiological and performance monitoring, and new types of touch/user interfaces, to name just a few. However, current fabrics are often unconventional, including device-mounted woven plastics or active-layer-covered fibers coated in polymer. These fabrics can have unfavorable aesthetics, discomfort, and limited pliability.

Wearable devices have many applications, including portable power generation, advanced physiological and performance monitoring, and new types of touch/user interfaces, to name just a few. However, current fabrics are often unconventional, including device-mounted woven plastics or active-layer-covered fibers coated in polymer. These fabrics can have unfavorable aesthetics, discomfort, and limited pliability.

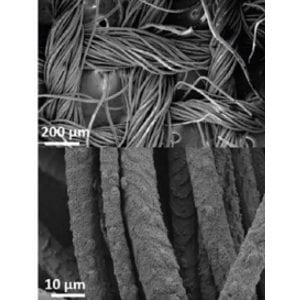

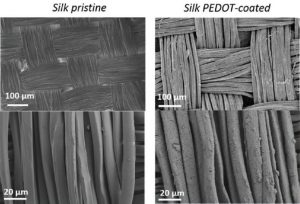

In Advanced Functional Materials, researchers from the University of Massachusetts Amherst and University of Wisconsin–Madison have demonstrated a vapor-coating technique to generate conducting-polymer-coated silk-, linen-, and bast-fiber fabrics (see figure, right) that can be used as circuit components in smart textiles and skin-mountable devices.

In Advanced Functional Materials, researchers from the University of Massachusetts Amherst and University of Wisconsin–Madison have demonstrated a vapor-coating technique to generate conducting-polymer-coated silk-, linen-, and bast-fiber fabrics (see figure, right) that can be used as circuit components in smart textiles and skin-mountable devices.

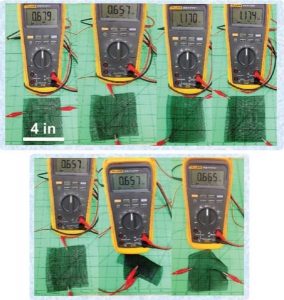

This vapor-coating process results in fabrics with deformation- and heat-stable conductivities (e.g., resistant to body heat or ironing); resistivities (see figure, left) that are linearly dependent on length, allowing for feasible incorporation into clothing; and adjustable electrical characteristics, controlled by altering fabric parameters post-synthesis by, for example, varying weave density or thread composition. In addition, and perhaps most important to the mass consumer market, they are outstandingly “wearable”, with the natural weight, feel, breathability, and mechanical/tensile properties of the uncoated fabric.