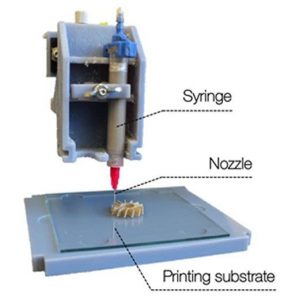

The ability to fabricate ceramics with complex, three dimensional shapes at many length scales is important to a number of emerging areas. Direct Ink Writing, or DIW, has become a versatile tool for this purpose, capable of printing ceramics over a wide range of length scales (0.01 – 1,000 mm) using inks based on micro- and nano-particles. DIW is particularly attractive for the fabrication of low-weight space hardware, where minimizing the structure’s mass is paramount to reducing mission costs. Despite its potential, additive manufacturing of ceramic space components has not been fully realized due to material processing challenges.

The ability to fabricate ceramics with complex, three dimensional shapes at many length scales is important to a number of emerging areas. Direct Ink Writing, or DIW, has become a versatile tool for this purpose, capable of printing ceramics over a wide range of length scales (0.01 – 1,000 mm) using inks based on micro- and nano-particles. DIW is particularly attractive for the fabrication of low-weight space hardware, where minimizing the structure’s mass is paramount to reducing mission costs. Despite its potential, additive manufacturing of ceramic space components has not been fully realized due to material processing challenges.

In new research by C. Larson et al. from Cornell University, DIW was used to print ultra-lightweight microwave components directly from silicon carbide. The ability to print SiC structures with tunable density is enabled by the use of SiC colloid and polymeric borosiloxane ink blends that are tuned for extrusion based printing, yet also convert/sinter into SiC at temperatures near 1,800 oC. The group modulated the polymer:colloid ratios within the ink to produce structures with relative densities ranging from 30 – 50%. Coupling this modular ink design with high-resolution patterning enabled the fabrication of thin-walled, high aspect-ratio SiC structures that are extremely lightweight. The authors used this material to 3D print microwave feedhorns to increase the signal to noise ratio of space optics. These feedhorns measured roughly 8 cm in length, yet weighed only ~3 grams; deploying an array of such structures would significantly reduce mass and costs relative to the machined counterparts currently used.