Microstructuring can introduce versatile repellent properties to surfaces. Special repellent properties can also be obtained by surface lubrication. Combining microstructuring and lubrication could result in new applications.

In Advanced Materials, Dr. Pavel Levkin from the Karlsruhe Institute of Technology and his co-workers report a novel hybrid interface that combines a superoleophobic, doubly re-entrant microtopography with a slippery lubricant-infused porous surface.

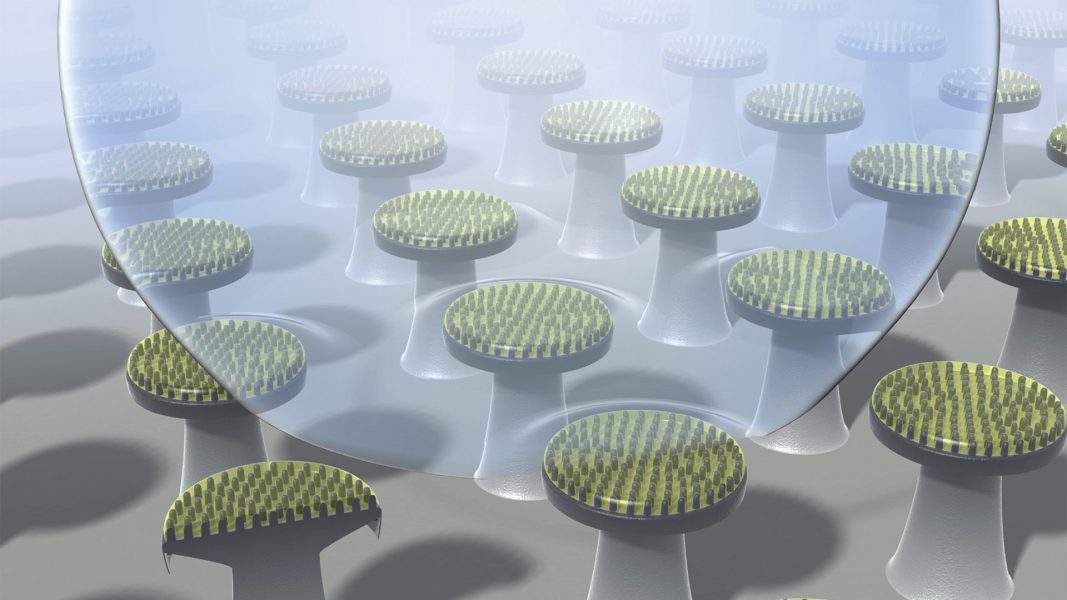

Dr. Pavel Levkin: “This was realized by using a very interesting novel 3D nanoprinting technology, called 3D direct laser writing based on two-photon absorption, in order to fabricate the doubly re-entrant micropillars—arrays of micropillars on the surface with the dedicated nanostructures on top of each micropillar.

These nanostructures, they stabilize the impregnated lubricant layer placed on top of each pillar, while the re-entrant geometry of the micropillars prevents this lubricant layer from spreading into the space between the micropillars. The slippery layer reduces the adhesion of liquid to the pillars, which was proved by another important novel surface characterization method, which is called scanning droplet adhesion microscopy, developed at Aalto University. The doubly re-entrant micropillars on the other hand, they make the surface superoleophobic and superhydrophobic.”

To learn more about this novel approach toward super-repellent surfaces, please visit the Advanced Materials homepage.