Over the past decade, the development of stretchable electronic devices and sensors has dramatically accelerated, concomitant with advances in functional materials and fabrication processes. Particularly, novel strategies have been developed to enable the biointegration of wearable electronic devices with human skin in ways that bypass the mechanical and thermal restrictions of traditional microfabrication technologies.

Despite all advancements in additive manufacturing, directly printing 3D structures and functional devices on biological and non-flat substrates remains a substantial challenge which requires, at least, closed-loop scan-and-print processes, biocompatible inks which can be processed under mild conditions, and a fundamental understanding of interfacial chemistries and mechanics.

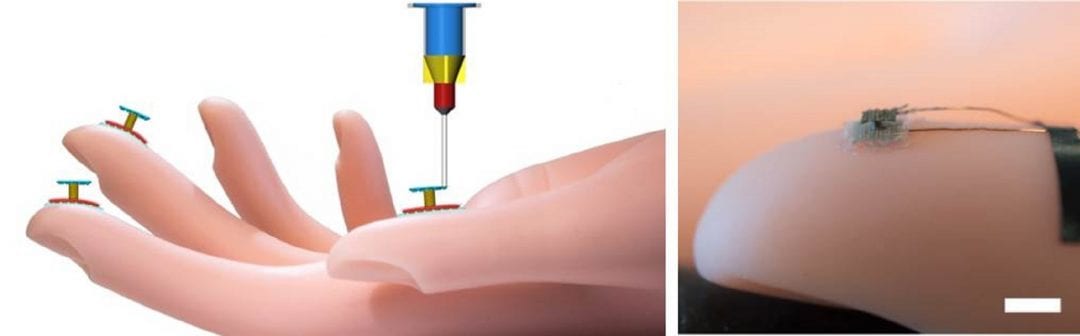

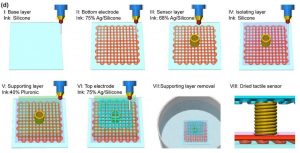

In a recent paper published in Advanced Materials, Michael C. McAlpine and his colleagues in University of Minnesota, USA, develop a series of novel inks, which can be cured at room temperature with tunable printability, high flexibility, electrical conductivity, and sensitivity. The inks have been used to manufacture 3D tactile sensors under mild conditions on a freeform surface using multi-material 3D printing and inverse engineering techniques. It has been demonstrated that the printed flexible, stretchable, and sensitive sensors are capable of detecting and differentiating human movements, including radial pulse, and finger pressing and bending.

This approach allows for the integration of multi-functional materials into complex 3D devices and sets the stage for conformally 3D printed devices directly onto the human body. Additionally, the entire process is performed at room temperature without curing or sintering in harsh conditions, which offers compatibility with various biological substrates and expansive applications in wearable and biomedical devices.

Image-coupled 3D multi-material printing approaches can facilitate customized wearable devices in previously inaccessible ways. This technology could pave the way toward the biointegration of various sensors in wearable electronics systems, and to advanced bionic skin applications.