For 75 years Empa has been conducting research on all aspects relating to wood. Beginning with an investigation into the properties of various types of indigenous woods, today this has grown into a research area with many branches – from fundamental research on the structure of wood to chemically or biologically modified woods, novel wood fiber products and surface technologies. Empa scientists examine each of the material’s properties in minute detail and use these results to develop next-generation techniques of utilizing wood such as in the areas of acoustic insulation and structural engineering.

In the beginning the focus was concentrated on research aimed at encouraging the exploitation of indigenous types of wood, according to Klaus Richter, who headed Empa’s Wood Laboratory for many years and who now teaches wood science at the Technical University, Munich. In the early days, for example, new processes for the pressure-impregnation of telegraph poles were developed, which significantly increased their useful life. Over time the field of research broadened, but the aim has remained the same, explains Tanja Zimmermann, Richter’s successor: developing innovative wood products which, in collaboration with industrial partners, can be economically exploited. This aspect is reflected in the new name of the laboratory: Applied Wood Research.

Basic research and applied development together

Ingo Burgert, Professor for Wood-Based Materials at the ETH Zürich and Empa, would like to link fundamental research and applied development. Image: Empa.

Exactly how this works in detail was explained by Ingo Burgert, professor of wood based materials at the ETH Zürich and simultaneously head of the Bio-inspired Wood Materials working group, at the recent Empa Wood Research symposium. Burgert is investigating the phenomenon of heartwood, which develops in trees after a certain age and frequently gives the material an enhanced durability. The professor is investigating questions such as whether it is possible to chemically modify wood after it has been harvested to make it harder and longer lived. Can one retrospectively fill wood with functional nanoparticles? Is it possible to construct composite materials of wood and carbon fiber? Francis Schwarze and Mark Schubert are also studying ways of altering the characteristics of wood in specific ways for particular applications, for example harnessing fungi which decompose wood to improve the tonal qualities for use in musical instruments, or utilizing enzymes to lend wooden surfaces completely new characteristics. This could perhaps make a wood surface resistant to fungus and bacteria. Another possibility is “self-adhesive” wooden chips for making fiberboard.

A range of interesting substances and materials can also be isolated from wood, one such being nanofibrillated cellulose (NFC), an extremely versatile material. Zimmermann’s team played (and continues to play) a central role in the further development of this material, which can be used in fiber reinforced adhesives and lacquers, and to make intervertebral disc implants. Airtight packaging for the food industry is another application for NFC’s – they are compostable and when burnt emit practically no pollutants.

From small to large

A more classical application is the use of wood as a construction material. René Steiger and Robert Widmann, two wood specialists from Empa’s Engineering Structures Laboratory, have been investigating load-bearing structures made of wood such as glue-laminated timber beams, which they destroy by applying extreme loads and then repair using carbon fiber mats affixed with adhesive, for example. The building industry profits from these optimized repair techniques. Wood is of course inflammable, but how quickly does it burn and how long does it maintain its load-bearing abilities? What happens when wood burns from the inside? These are questions which Empa investigates in its Fire Laboratory. For instance, just in front of the flame front a large quantity of water vapor is forced through the wood.

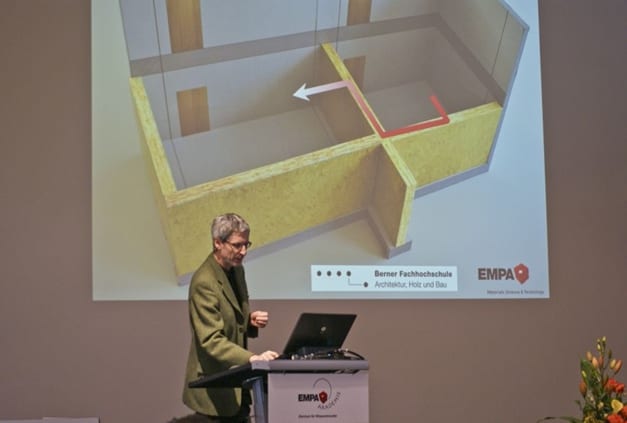

The lightweight structure problem: how does acoustic energy propagate through a wooden house? Kurt Eggenschwiler, of Empa's Acoustic Laboratory explains the details. Image: Empa.

As a result of further advances in the fire safety regulations in Switzerland, multistoried wooden buildings have been permitted in the country for several years now. This development raises new questions, though: how good is the acoustic installation in a wooden-shelled building? A team led by Kurt Eggenschwiler, head of Empa’s Acoustics/Noise Control Laboratory, has been studying this topic since 2011 with the help of a special lightweight testing structure that allows the scientists to investigate and evaluate the acoustic qualities of lightweight structures made of wood and composite materials.

Wood research–Empa’s role in Switzerland

The symposium ended with a series of guest lectures, underscoring the important role which Empa plays in the Swiss wood industry. Martin Riediker of the Innovation Promotion Agency (CTI) explained the National Research Program “Resource Wood” project (NFP 66), initiated in 2010. The aim of this initiative is to better exploit ageing Swiss timber resources and to find new applications for wood. Christoph Starck of Lignum, the umbrella organization for the Swiss forestry and lumber industry, described how the results of wood research are applied in practice in the building industry. From Empa researcher to carpenter – everyone involved in dealing with wood is working towards the same goal, namely utilizing a sustainable, regrowable raw material in an optimal manner.

Source: Empa