The global market for adhesives for 2019 is estimated at $50 billion. That’s a lot of glue. With numerous applications in various industries, adhesives have become practically indispensable for today’s modern life. However, in recent years there has been a demand for more sustainability and adhesives based on renewable raw materials.

That was the focus of a team of researchers from Purdue University who have discovered a method for using tannic acid to help create improved adhesives, coatings, and manufacturing composites. Tannic acid is a well-known form of tannin, a type of polyphenol that is usually extracted from plants. The Purdue team is using its discovery for epoxy-based polymers, which are considered among the most versatile and useful adhesive agents because of their excellent mechanical strength and strong sticking power.

Jeffrey Youngblood, a professor of materials engineering at Purdue’s College of Engineering, has extensive experience in developing sustainable materials. He previously worked on technologies involving tannic acid to help make materials flame-retardant.

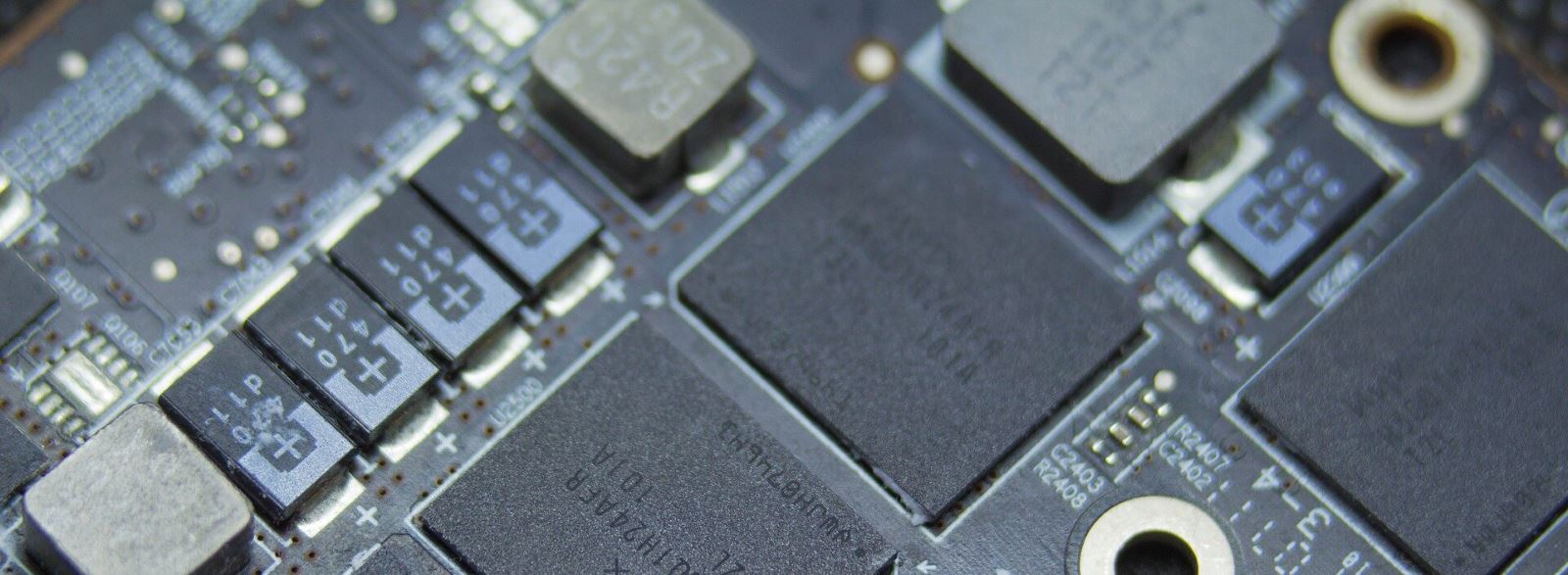

“There are few high-temperature hardeners that are sustainable. Our technology is designed to improve sustainability without sacrificing performance,” says Youngblood in the company’s press release. Epoxy polymers are used in a wide range of applications including coatings, adhesives, structural composites, insulating materials and components of electronics. A hardening agent ensures stability and stiffness in high-temperature environments.

“We are using tannic acid as the hardener. It is more sustainable than other options, has less environmental impact and is relatively inexpensive,” Youngblood explained. In addition, the tannic acid solution was also shown in testing to be stable and maintain the required stiffness when exposed to high temperatures.

“Sustainable materials typically have lower performance, which compromises the public perception and penetration into the market. Here, such a trade-off is not necessary,” Youngblood concluded. The research team are currently working to patent the technology and say they are looking for additional partners and those interested in licensing the technology.