Researchers at Tsinghua University, Beijing, have developed a renewable material made from soy protein that could power the next generation of solid-state batteries with high efficiency and long lifespans.

Solid-state batteries have been hailed as the successor to lithium-ion battery technologies used everywhere today from smartphones to electric vehicles. The core innovation in solid-state batteries lies in the electrolyte, an essential component of any battery that acts as a bridge between the electrodes, allowing metal ions to travel through it to generate electricity. As their name implies, solid-state batteries replace conventional liquid electrolytes with solid materials, enabling faster charging and potentially doubling energy storage capacity.

Development is still underway to make solid-state batteries competitive with other batteries in both performance and cost. A solution that is increasingly gaining attention consists of using renewable materials to make solid electrolytes, offering a way to reduce the environmental impact of battery manufacturing while improving battery performance and safety.

“Our research advances the use of green and sustainable biomass materials in the field of battery science and technology, contributing to creating a cleaner, more efficient, and sustainable future,” says Yang Shen, a professor at Tsinghua University and an author of the study. “Compared to traditional solid electrolytes, the high-performance solid electrolytes developed using renewable [soy protein] help reduce waste generation and minimize environmental impact.”

From soybeans to high-end batteries

Soy protein is a renewable, low-cost material that can be grown in abundance, making it an ideal candidate to make affordable, environmentally friendly batteries. The natural structure of the soy proteins allows ions to travel through them, while simultaneously enabling scientists to easily modify the material and tailor its properties to suit a wide range of applications.

“Primarily used in the food and medical industries, its accessibility, non-toxicity, and biodegradability make [soy protein] a promising material for potential applications in other fields,” says Shen.

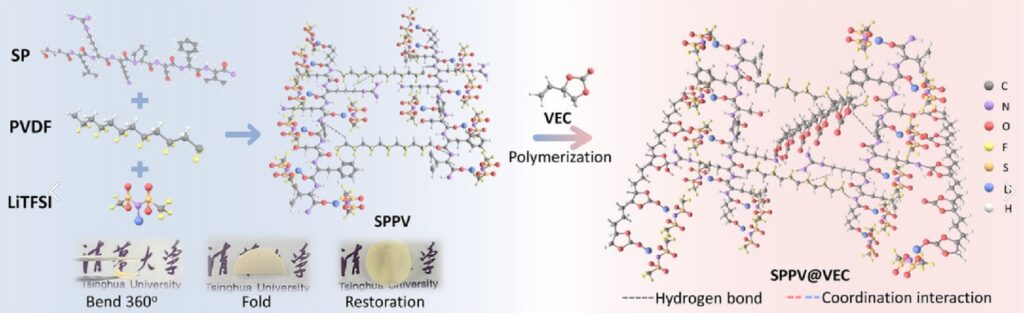

To make a material suitable for batteries, his research team chemically modified soy proteins to increase their natural conductivity, helping lithium ions travel through more easily. The resulting material consists of a three-dimensional network of hard and soft layers that make the electrolyte tough and flexible at the same time.

A solid-state lithium battery built using this soy-based electrolyte was able to stably charge and discharge for 2,000 hours at 60°C. When the temperature was raised to 120°C, the battery retained nearly 75% of its capacity for over 800 charging cycles, showing potential for applications that require reliable performance at high temperatures. In contrast, conventional lithium-ion batteries are typically unstable at temperatures over 60°C, which severely impacts their performance and can pose safety risks such as the leakage of toxic and highly flammable compounds.

Additionally, the soy-based material could address a major challenge for many electrolytes currently in development: As a battery charges and discharges, a chemical reaction can occur between the electrolyte and the electrodes that deposits chemicals to create an interface layer. If this layer is not stabilized, it will keep growing with every charging cycle, slowly reducing the battery’s performance over time.

Batteries built with the soy-based material created a thin and uniform interface between the electrolyte and electrodes that remained stable over time. Moreover, the interface layer was flexible, allowing it to expand and contract with the battery as it cycles, preventing cracks.

A lifecycle assessment showed that the manufacturing of the soy-based material would have a lower environmental impact with regard to acidification, release of carcinogens, and fossil fuel use compared to other organic electrolyte materials that have shown promise in solid-state battery applications. The soy protein electrolyte also showed a significantly lower release of toxic or flammable volatile compounds compared to other materials.

“These results demonstrated that [soy-based] materials hold great potential in the field of energy storage and provide a promising route toward biomass-based solid electrolytes,” says Shen.

While more work will be needed to refine this material and make it suitable for large-scale production of next-generation batteries, soy protein could one day become the foundation for eco-friendly batteries with long lifespans. In particular, Shen and colleagues see promise for applications in electric vehicles and electronic devices, especially for any use cases where batteries may need to reliably work under extreme temperatures.

Featured image credit: Pete Linforth via Pixabay