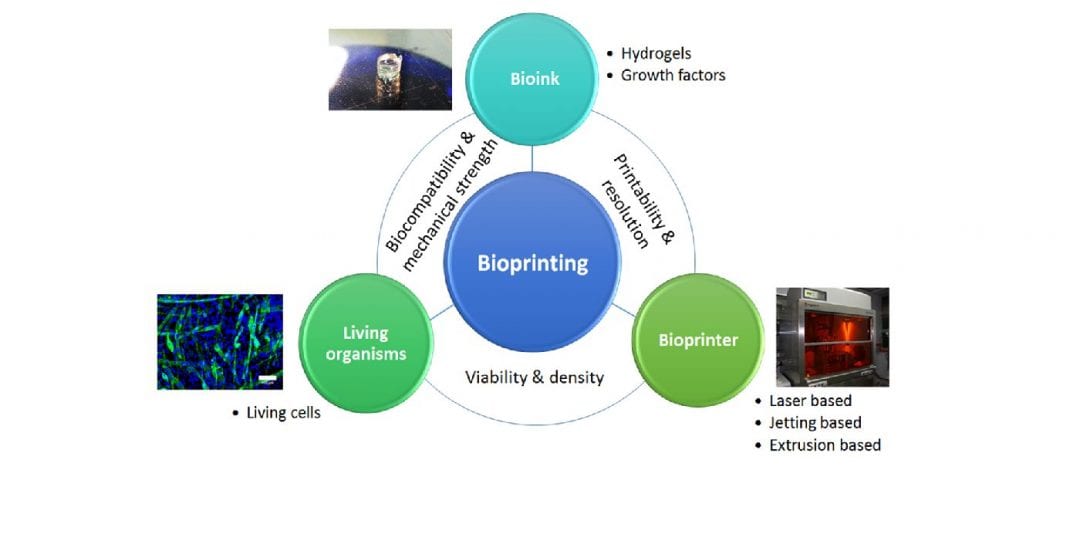

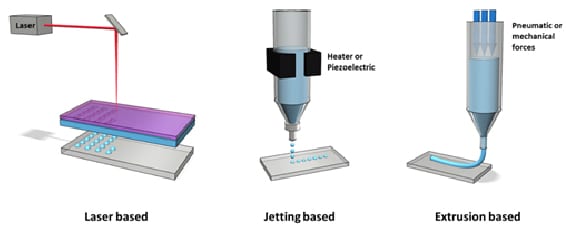

Bioprinting is a breakthrough technology that integrates living cells, biomaterials and a robotic dispensing system to create complex structures that mimic original tissues and organs. Moreover, bioprinting addresses interface issues between robotic automation and living materials. This technology has good repeatability, high precision and adequate scalability, which are important for tissue-substitute fabrication and may potentially lead to organ printing. One of the main components of bioprinting is the bioink, and hydrogels are essential in bioink formulation. In bioprinting, hydrogels should have good biocompatibility, provide good resolution and have sufficient mechanical strength to support printed structures.

Thermo-responsive hydrogels are good candidates for bioprinting because they have unique characteristics like reversible sol-gel transition upon temperature change and an adjustable printability by controlling physical crosslinking. The properties and use of thermo-responsive hydrogels in bioprinting including gelation mechanism, concentration, sol-gel temperature, bioprinter mode, shape after printing, cell viability and future perspectives, have been discussed in a recent review by R. Suntornnond et. al.

While thermo-responsive hydrogels are very useful for tissue engineering applications and have become part of the advancement in bioprinting technology, there are some obstacles to be overcome. Vascularization for example remains as the main problem in order to provide long sustainability for developing tissue into organs. A highly printable hydrogel is needed to create vascularization, meanwhile it also has to possess bioactive features to provide a suitable environment for cells to grow. The current conflict is that some hydrogels show a good biocompatibility while exhibiting poor printability (either low shape fidelity or low resolution) or vice versa. Hence, it remains very difficult to create a complex 3D structure. Lastly, just good printability and bioactivity may not be sufficient because hydrogels for tissue engineering applications must also provide adequate mechanical strength to support the tissue construct. Novel thermo-responsive hydrogels must be developed in order to meet all of these requirements.