Graphene is being employed for ever more types of flexible products. Unfortunately, traditional microfabrication techniques limit the scalability of potentially application-ready technologies. The economically viable production of miniaturized electronics, for example, requires low costs and a high throughput, which cannot be satisfied by the current protocols. Researchers are therefore turning to new technologies to realize advanced micro-electronics, but the methods such as laser scribing now being explored could mean high levels of waste, and it is less clear how they could be integrated with other electronics.

One electronic component of interest is the micro-supercapacitor (MSC), an energy-storage device which charges/discharges quickly and has a high power density and long cycle life. The physical and electrical properties of graphene make it an ideal material for MSCs, providing the potential for flexible electronics.

A team working at the University of Minnesota and Northwestern University, USA, has now developed a printing method to produce such flexible graphene MSCs with a planar architecture suitable for integration in portable electronic devices.

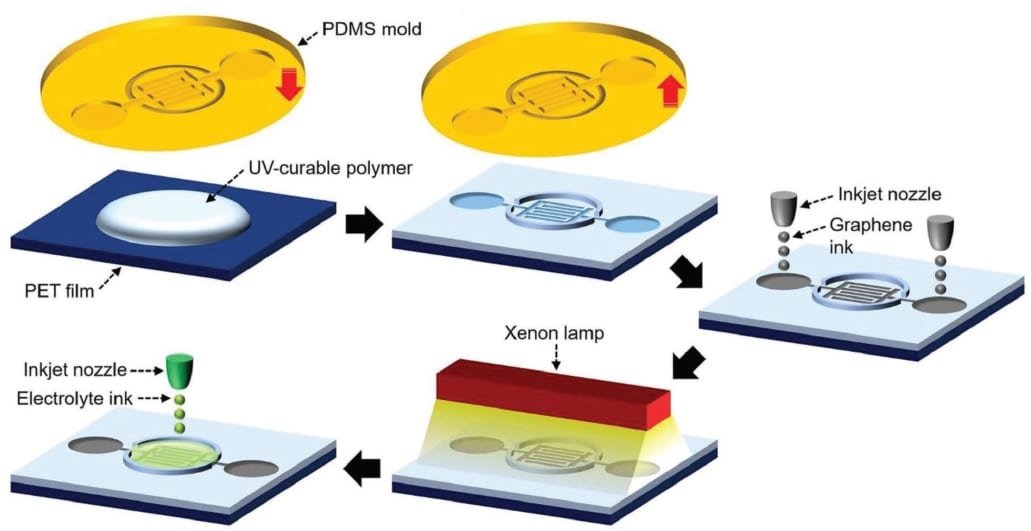

Their process, denoted ‘self-aligned capillarity-assisted lithography for electronics’ (SCALE), begins with the creation of a polymer template, generated by stamping a UV-curable polymer with a PDMS mold. High-resolution inkjet printing is then used to deposit a graphene ink into the template, which is annealed using a xenon lamp to form the electrodes. In the final step, a polymer gel electrolyte is printed onto the template over the electrodes to complete the configuration.

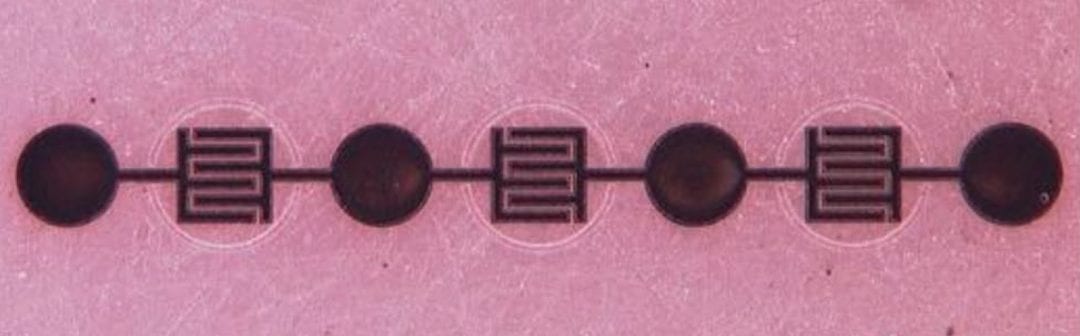

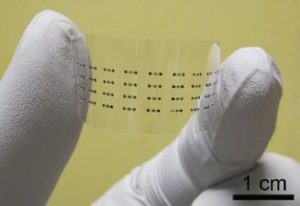

The graphene ink is formulated from pristine graphene, shear-mix exfoliated from graphite flakes using a polymer stabilizer. A cyclohexanone/terpineol/di(ethylene glycol) methyl ether solvent system is used to provide a shear viscosity of just 8–12 mPa s, ensuring good capillary channel wicking of the ink during printing. The PDMS stamp can be used multiple times, and there is the potential for scalable roll-to-roll processing of graphene electronics, including complex interdigitated architectures, using this technique.

The graphene ink is formulated from pristine graphene, shear-mix exfoliated from graphite flakes using a polymer stabilizer. A cyclohexanone/terpineol/di(ethylene glycol) methyl ether solvent system is used to provide a shear viscosity of just 8–12 mPa s, ensuring good capillary channel wicking of the ink during printing. The PDMS stamp can be used multiple times, and there is the potential for scalable roll-to-roll processing of graphene electronics, including complex interdigitated architectures, using this technique.

Arrays of MSCs were printed onto a flexible PET film and their electrochemical performance was tested. Satisfyingly, all printed devices were found to be functional, and it was determined that fewer electrode fingers provided a higher specific capacitance value, with larger energy and power densities.

More details can be found in their Advanced Energy Materials communication. Check it out now on the Wiley Online Library.