Representing the most advanced addition to the Olympus opto-digital range, the new LEXT OLS4100 3D laser scanning microscope offers a faster and easier approach to optical metrology, combining optical precision with the intuitive operation of a digital interface.

Representing the most advanced addition to the Olympus opto-digital range, the new LEXT OLS4100 3D laser scanning microscope offers a faster and easier approach to optical metrology, combining optical precision with the intuitive operation of a digital interface.

The new model builds upon the success of its predecessor, the LEXT OLS4000, and presents several major benefits over traditional stylus-based contact approaches to surface inspection, enhancing both efficiency and accuracy, while avoiding sample damage.

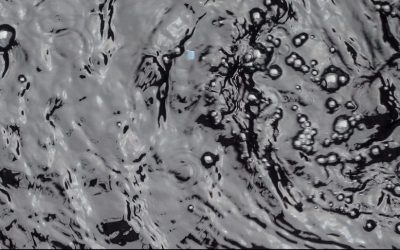

Samples of a large range of sizes are easily analysed, and navigation around the sample is straightforward even at higher magnifications, as a wide-field area map display of the sample under low magnification is always visible. Furthermore, the field of view is now expanded, with updated image stitching functions. A single image is seamlessly constructed from many individual captures, which can then be viewed and measured in either 2D or 3D. The boundaries of the stitching area can be automatically detected, or the exact area can instead be manually specified by tracing around a sample of any shape.

Image acquisition is faster and more flexible on the LEXT OLS4100, with a variety of scan modes available. By automatically adjusting for the Z-axis position, the Smart Scan mode restricts image acquisition to the focal plane, for rapid scanning in high-resolution 3D across large areas. Ultra-fast mode is approximately nine times faster than Fine mode, employed in applications demanding the highest level of precision. For even faster, targeted acquisition of a specified area, the Band Scan mode will only scan the user-specified region, instead of the whole sample.

Imaging through multiple layers is now possible with the new Multi-Layer mode, which recognises each separate layer as a distinct focal plane along the Z-axis. Accurate inspection and measurement of each layer is achieved, even when measuring the roughness and thickness of multiple transparent layers, for example a transparent resin layer over a glass substrate.

Visit the Olympus website for more information on the new LEXT OLS4100 at: www.olympus-ims.com/en/metrology/ols/

Source: Olympus